Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the World of Die Casting Tools and Techniques for Precision Manufacturing

Understanding Die Cast Dies A Key Component in Metal Casting

Die casting is a manufacturing process that involves forcing molten metal under high pressure into a mold, known as a die. This method is widely used in various industries due to its efficiency, precision, and ability to produce complex shapes. At the heart of this process lies the die cast die, which serves as the main tool for shaping the molten metal into a desired form.

What Are Die Cast Dies?

Die cast dies are specialized molds made from high-strength materials, typically steel or aluminum, designed to withstand the immense pressure exerted during the die casting process. They are engineered to create parts with tight tolerances and excellent surface finishes. Die cast dies can range from simple designs to highly intricate configurations depending on the requirements of the final product.

Types of Die Cast Dies

1. Single Cavity Dies These dies are designed to produce a single part in each cycle of the casting process. They are often used when manufacturing low volumes of parts or prototypes.

2. Multi-Cavity Dies As the name suggests, these dies can produce multiple parts simultaneously. They are ideal for high-volume production runs, enhancing production efficiency and reducing costs per unit.

3. Family Dies This die type can produce different parts in a single cycle. Family dies are useful for manufacturers producing a variety of related components, allowing for flexibility and minimizing setup time.

4. Cold Chamber vs. Hot Chamber Dies The choice between these two types of dies depends on the metal being cast. Cold chamber dies are used for metals that have high melting points, while hot chamber dies are suitable for metals with lower melting points like zinc and magnesium.

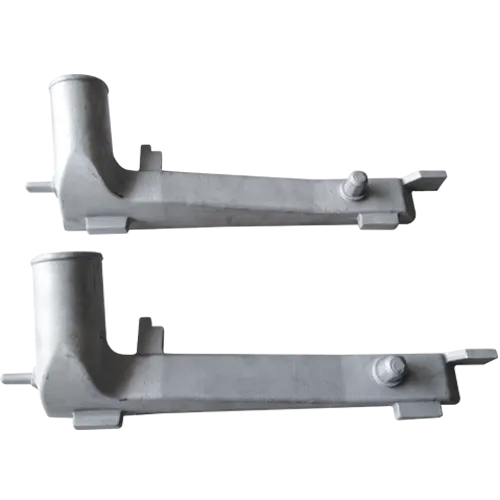

die cast dies

The Importance of Die Cast Dies

Die cast dies play a crucial role in the overall quality and efficiency of the die casting process. Their design directly impacts the dimensional accuracy, surface finish, and structural integrity of the final product. A well-designed die can significantly reduce scrap rates, lower production costs, and improve the overall throughput of the manufacturing process.

Moreover, the life expectancy of a die cast die is an important consideration in die design. High-quality dies can withstand many cycles of casting before needing replacement or repair, making them a cost-effective solution for manufacturers. The selection of materials, cooling systems, and surface treatments are all key factors in prolonging the die's lifespan.

Recent Innovations in Die Casting Technologies

As technology advances, so too does the design and manufacture of die cast dies. Recent innovations include the use of advanced simulation software, which allows engineers to analyze and optimize the flow of molten metal within the die before actual production begins. Additionally, the incorporation of smart manufacturing techniques, such as real-time monitoring and automated adjustments, has increased the efficiency and consistency of the die casting process.

Furthermore, the rise of additive manufacturing has opened new avenues for die design. 3D printing can produce complex die geometries that were previously impossible to manufacture, leading to improved cooling channels and reduced cycle times.

Conclusion

In conclusion, die cast dies are an essential component of the die casting process, significantly affecting the quality and efficiency of metal parts production. By understanding the various types of dies and their importance, manufacturers can make informed decisions that enhance productivity and product quality. As technology evolves, so too will the methods and materials used in die casting, making it a continually advancing field poised for future growth and innovation.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025