Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits of Die Cast Aluminum Castings in Modern Manufacturing Processes

The Evolution and Advantages of Die Cast Aluminum Castings

Die cast aluminum castings have become an integral component in various industries, thanks to their strength, lightweight properties, and versatility in design. This manufacturing process has evolved significantly over the years, positioning aluminum as a material of choice for many applications. In this article, we will explore the benefits of die cast aluminum, its applications, and the future of this innovative manufacturing technique.

Die casting is a process that involves forcing molten metal into a mold cavity under high pressure. This method is highly efficient and allows for the production of complex shapes with high dimensional accuracy. When aluminum is used in die casting, several advantages arise, making it a favored choice for manufacturers.

One of the primary benefits of die cast aluminum is its outstanding strength-to-weight ratio. Aluminum is significantly lighter than many other metals, which contributes to the production of lightweight components that do not compromise on strength. This characteristic is particularly advantageous in industries such as automotive and aerospace, where reducing weight can lead to improved fuel efficiency and performance. Additionally, aluminum is resistant to corrosion, which enhances the durability of the castings and extends their lifespan in various environments.

Another advantage of die cast aluminum castings is their ability to be produced in large volumes with consistent quality. The precision of the die casting process ensures that each component produced meets specified tolerances and surface finishes. This quality control is crucial in applications where safety and reliability are paramount, such as in the automotive industry. Companies can achieve economies of scale by utilizing die cast aluminum, thereby reducing production costs and making it an economically viable option for mass production.

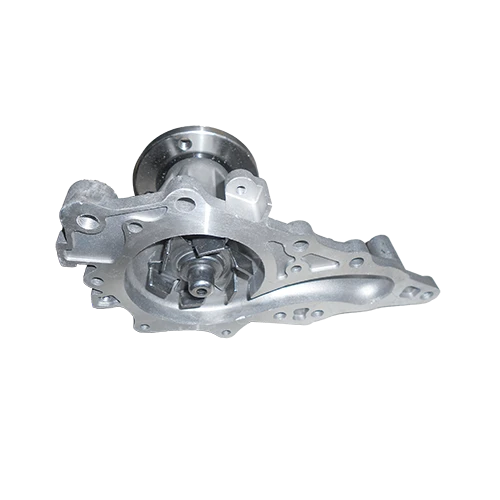

die cast aluminum castings

Moreover, die cast aluminum allows for intricate designs that would be challenging or impossible to achieve with other manufacturing methods. The process supports complex geometries, enabling designers to create lightweight, yet strong parts that feature a variety of shapes and features. This flexibility in design expands the possibilities for innovation, leading to the creation of more efficient and effective products.

The applications of die cast aluminum castings are vast, ranging from automotive parts like engine blocks and transmission housings to consumer electronics enclosures, medical devices, and industrial machinery components. As the demand for lightweight and energy-efficient products continues to rise, the use of die cast aluminum is expected to increase, further cementing its role in modern manufacturing.

Looking toward the future, advancements in die casting technology are paving the way for even greater efficiencies and capabilities. Innovations such as improved mold designs, better melting processes, and the integration of automation and robotics are enhancing production speeds and reducing waste, thus making die cast aluminum even more appealing to manufacturers. Additionally, as sustainability becomes a critical factor in production, the inherent recyclability of aluminum can help industries meet environmental standards and reduce their carbon footprint.

In conclusion, die cast aluminum castings offer numerous advantages that support their widespread use across various industries. With their combination of strength, lightweight properties, dimensional accuracy, and versatility, they meet the demands of modern manufacturing. As technology continues to advance, the future of die cast aluminum looks promising, ensuring that it will remain a vital component in innovative designs and efficient production methods for years to come.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025