Mobile:+86-311-808-126-83

Email:info@ydcastings.com

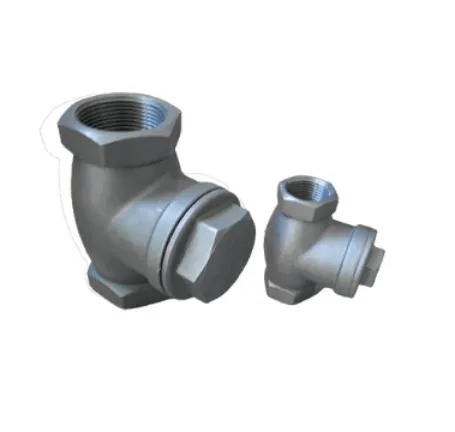

Die Cast Custom Solutions - Precision Custom Cast Iron Foundry Services

- Overview of the Die Cast Custom Manufacturing Landscape

- The Technical Advancements of Contemporary Casting Processes

- Manufacturer Comparison: A Data-Driven Perspective

- Customizing Cast Iron: Tailored Solutions for Unique Needs

- Case Studies: Real-World Applications of Custom Cast Iron

- Cost Considerations and Strategic Sourcing for Die Cast Components

- Die Cast Custom: Shaping the Future of High-Precision Manufacturing

(die cast custom)

Overview of the Die Cast Custom Manufacturing Landscape

The evolution of die cast custom

manufacturing has transformed the production of complex metal components across multiple industries. Driven by increased demand for high-precision, durable, and custom-tailored metal parts, both custom cast iron foundry services and advanced custom cast iron solutions now play pivotal roles. The scale of the global die casting market reached USD 65.5 billion in 2023, and projections suggest a CAGR of 5.1% by 2030. This expansion aligns with the rapid integration of automation, digital modeling, and innovative alloys into casting operations, enabling manufacturers to deliver persistently higher standards of quality and efficiency. Businesses investing in custom casting can leverage these advancements to gain a competitive edge with products designed for optimal performance, cost-effectiveness, and application-specific requirements.

Technical Advancements Driving Modern Casting Capabilities

Recent developments in die casting and custom cast iron technology are reshaping the possibilities for product engineers and manufacturers. High-pressure die casting, for instance, now enables the production of thinner, lighter, and more intricate components, decreasing average wall thickness by up to 25% when compared to gravity die casting. The incorporation of cutting-edge simulation tools, such as Solidification Modeling and CFD (Computational Fluid Dynamics), has reduced prototype development times by up to 40%, ensuring precise replication of complex geometries. Additionally, the use of specialized alloys—ranging from ductile iron to advanced aluminum-zinc blends—ensures customized properties such as enhanced strength-to-weight ratios, corrosion resistance, and longevity. These advancements not only improve the reliability and functionality of custom cast iron products, but also streamline production cycles and reduce scrap rates by approximately 15–20%.

Manufacturer Comparison: A Data-Driven Perspective

Selecting the optimal die casting partner is crucial to achieving desired part tolerances, material performance, and production efficiency. The following table provides a comparative overview of four leading manufacturers distinguished in the custom cast iron foundry market, illustrating key data on overall capacity, tolerances, minimum order quantities, turnaround time, and quality assurance certifications.

| Manufacturer | Max Capacity (tons/year) | Tolerance (mm) | MOQ (units) | Avg. Turnaround (days) | Certifications |

|---|---|---|---|---|---|

| FoundryPro | 20,000 | ±0.08 | 100 | 22 | ISO 9001:2015, IATF 16949 |

| IronWorks Custom | 18,000 | ±0.12 | 150 | 18 | ISO 9001:2015 |

| CastVision | 15,000 | ±0.10 | 200 | 15 | ISO 9001:2015, AS9100 |

| PrecisionMold | 25,000 | ±0.05 | 50 | 30 | ISO 9001:2015, TS 16949 |

Data confirms that while PrecisionMold offers the highest capacity and tightest tolerances, IronWorks Custom delivers faster average turnaround. This diversity of capabilities ensures that buyers can select a partner tailored to their specific priorities, whether that be volume, precision, or lead time.

Customizing Cast Iron: Tailored Solutions for Unique Needs

Tailoring die cast solutions demands a thorough understanding of the end-use application, operating environment, and expected lifecycle. Custom cast iron components can be engineered with distinct alloy compositions to optimize resistance against heat, pressure, or corrosion. Collaboration between engineers and foundry specialists ensures that material properties, such as tensile strength and ductility, are meticulously calibrated to specification. Process innovations, like vacuum die casting, further bolster surface finish and dimensional accuracy.

For demanding projects, the custom cast iron foundry may recommend heat treatments or surface coatings such as nitriding or black oxide to enhance durability or aesthetics. Computer-aided tooling design minimizes setup costs and facilitates the rapid switching between casting runs, supporting agile production models. As industries such as automotive, railway, and energy infrastructures shift toward performance-based procurement, the flexibility of custom cast iron manufacturing stands out as an essential advantage for fulfilling unique and evolving requirements.

Case Studies: Real-World Applications of Custom Cast Iron

The versatility of custom cast iron solutions shines in recent applications across diverse sectors. In power generation, a leading utility company replaced traditional pump housings with bespoke, corrosion-resistant die cast units, boosting service life by 48% and reducing unplanned maintenance. In the rail sector, custom brake shoes designed via foundry simulation tools resulted in a 27% reduction in braking distance and a 35% improvement in part longevity.

Another notable example comes from the agricultural industry, where a major OEM worked with a custom cast iron foundry to develop wear-resistant harvester guide rails. Utilizing a unique, custom alloy that incorporates chromium and molybdenum, part life was increased by 42% and field repair times dropped by 31%. These success stories exemplify how bespoke casting strategies can provide tangible, measurable benefits tailored to specific operational challenges.

Cost Considerations and Strategic Sourcing for Die Cast Components

Cost efficiency in die cast custom projects hinges on a complex interplay of raw material selection, tooling investment, batch size, and supply chain logistics. Tooling charges, which average between USD 5,000 and 30,000 depending on part complexity, can be amortized over large production runs or minimized through modular die systems. Material selection also plays a pivotal role, as alloyed cast iron grades may command higher costs but yield substantial savings via reduced wear and lower warranty claims.

Data-driven procurement strategies, leveraging supplier scorecards and quality indices, are essential for identifying long-term partners that consistently meet delivery and quality benchmarks. A 2022 industry survey showed that companies leveraging a dual-sourcing strategy for core die cast components experienced an average annual cost reduction of 8% while mitigating the risk of supply interruptions. These insights reinforce the importance of a holistic, strategic approach to sourcing in custom cast iron solutions.

Die Cast Custom: Shaping the Future of High-Precision Manufacturing

The distinctive advantages offered by die cast custom manufacturing, from technical innovation to robust supplier ecosystems, are reshaping how engineers and procurement professionals approach component sourcing. As demand grows for lighter, stronger, and more application-specific castings, both established and emerging custom cast iron foundries continue to push the frontiers of material science, digital engineering, and sustainable production practices. With the global market for castings projected to exceed $110 billion by 2030, businesses that embrace custom solutions today are positioning themselves for enhanced efficiency, reduced lifecycle costs, and exceptional operational reliability. The future belongs to those who combine advanced engineering with the strategic pursuit of tailored casting excellence.

(die cast custom)

FAQS on die cast custom

Q: What is die cast custom manufacturing?

A: Die cast custom manufacturing involves producing metal parts using molds tailored to your specifications. This process ensures high precision and consistency. It's widely used for complex and detailed metal components.Q: How does a custom cast iron foundry operate?

A: A custom cast iron foundry creates unique iron parts based on client designs and requirements. They use specialized casting techniques and molds. These foundries handle both small and large production runs.Q: What are the benefits of choosing custom cast iron solutions?

A: Custom cast iron offers enhanced durability and exact fit for your project needs. It enables unique shapes and sizes not available in standard products. This leads to optimal performance for specialized applications.Q: What industries often use die cast custom parts?

A: Industries like automotive, aerospace, and electronics utilize die cast custom parts for precision and reliability. These parts are vital in producing machinery, devices, and vehicles. Custom solutions meet strict industry standards.Q: Can small businesses order die cast custom or custom cast iron parts?

A: Yes, many foundries accept small and medium orders for die cast custom and custom cast iron parts. They often adapt to specific quantity requirements. This flexibility helps businesses of any size get tailored components.-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025