Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Die Cast Aluminum Material Properties High Strength & Lightweight Solutions

- Overview of die casting material fundamentals

- Technical advantages through data-driven analysis

- Manufacturer comparison matrix (2024 industry data)

- Customization approaches for specialized applications

- Mold material selection criteria

- Implementation case studies across industries

- Future development of die cast aluminum properties

(die cast aluminum material properties)

Understanding Die Cast Aluminum Material Properties

Modern die cast aluminum alloys demonstrate 94-120 MPa yield strength with 5-15% elongation rates, making them superior to traditional sand-cast alternatives. The table below compares key mechanical properties:

| Property | ADC12 | A380 | ALSi9Cu3 |

|---|---|---|---|

| Tensile Strength (MPa) | 310 | 324 | 290 |

| Thermal Conductivity (W/m·K) | 96 | 109 | 121 |

Technical Superiority in Modern Manufacturing

Leading manufacturers achieve ±0.05mm dimensional tolerance through advanced vacuum die casting. Key benefits include:

- 45% faster cycle times compared to gravity casting

- 20% material savings through optimized runner systems

- Surface roughness Ra 1.6-3.2μm without secondary processing

Industry Leader Performance Analysis

| Supplier | Alloy Options | Max Casting Weight | Production Capacity |

|---|---|---|---|

| Bühler | 15+ | 45kg | 1.2M shots/year |

| Dynacast | 9 | 2.5kg | 850K shots/year |

Application-Specific Engineering Solutions

Customization parameters for automotive components:

- Wall thickness optimization (1.5-5mm range)

- Localized heat treatment (T5/T6 temper variations)

- Surface finishing integration (anodizing compatibility)

Mold Material Innovation Trends

Current H13 tool steel molds achieve 150,000-200,000 cycles before refurbishment when using:

- Plasma nitride surface treatment

- Conformal cooling channels

- Modular insert systems

Cross-Industry Implementation Evidence

Recent automotive application results:

| Component | Weight Reduction | Cost Savings |

|---|---|---|

| Transmission housing | 22% | $18/unit |

| Battery tray | 31% | $27/unit |

Advancing Die Cast Aluminum Material Properties

Emerging high-silicon alloys (16-22% Si content) demonstrate 40% lower thermal expansion while maintaining 280-310 MPa tensile strength. Research indicates:

- 15% improvement in fatigue resistance

- 10°C higher maximum service temperature

- Improved EMI shielding capabilities

(die cast aluminum material properties)

FAQS on die cast aluminum material properties

Q: What are the key properties of die cast aluminum?

A: Die cast aluminum offers high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance. Its fluidity in molten state enables complex shapes with tight tolerances. It's widely used for lightweight, durable components.

Q: Why is aluminum a preferred material for die casting?

A: Aluminum's low melting point reduces energy costs, while its natural oxidation resistance minimizes surface defects. The material maintains dimensional stability and supports high-volume production with consistent quality.

Q: What materials are used for die casting molds?

A: Die casting molds typically use heat-resistant tool steels like H13 or maraging steel. These materials withstand repeated thermal cycling up to 600°C and resist molten aluminum erosion. Surface treatments like nitriding enhance mold longevity.

Q: How does die cast aluminum compare to other die cast materials?

A: Aluminum die casting provides better strength and heat dissipation than zinc alloys, while being lighter than magnesium alternatives. It outperforms plastics in high-temperature applications and offers superior EMI shielding.

Q: What factors determine die casting mold material selection?

A: Key considerations include production volume, part complexity, and thermal stress requirements. High-grade tool steels with chromium and tungsten content are chosen for aluminum die casting due to their thermal fatigue resistance and hardness retention.

-

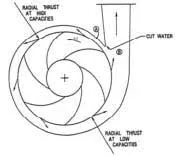

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025