Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Functionality and Design of Compressor Impellers in Engineering Applications

Understanding Compressor Impellers Design and Functionality

Compressor impellers play a critical role in various industrial applications, ranging from aerospace engines to HVAC systems. These components, typically made from high-strength materials, are designed to convert rotational energy from the compressor's motor into kinetic energy, effectively moving air or gas through the system. To comprehend the significance of compressor impellers, it is essential to explore their design, functionality, and the factors influencing their performance.

What is a Compressor Impeller?

A compressor impeller is essentially a rotating blade assembly within a centrifugal compressor. The main objective of the impeller is to increase the pressure of the gas or air being processed. As the impeller rotates, it dramatically increases the velocity of the incoming fluid, which then passes through a diffuser where kinetic energy is converted into pressure energy. This fundamental principle allows compressors to work efficiently across various settings.

Design Considerations

The design of compressor impellers is a complex process that takes into account several factors, including aerodynamic efficiency, strength, and material selection. Here are some of the critical design elements

1. Blade Geometry The shape and angle of the blades are crucial to the performance of the impeller. Designers must optimize the blade profile to minimize losses due to turbulence while maximizing the flow of air or gas.

2. Number of Blades The number of blades on an impeller can vary depending on the specific application. More blades can improve efficiency and pressure ratio but may also lead to increased drag and reduced maximum flow rates.

3. Material Selection Impellers must withstand high rotational speeds and pressures. Therefore, materials with high tensile strength, corrosion resistance, and fatigue properties, like titanium or advanced composites, are often chosen.

4. Surface Treatment To enhance performance and longevity, impeller surfaces may undergo treatments to reduce friction and improve aerodynamics. Coatings can also protect against corrosive elements in the gas or air.

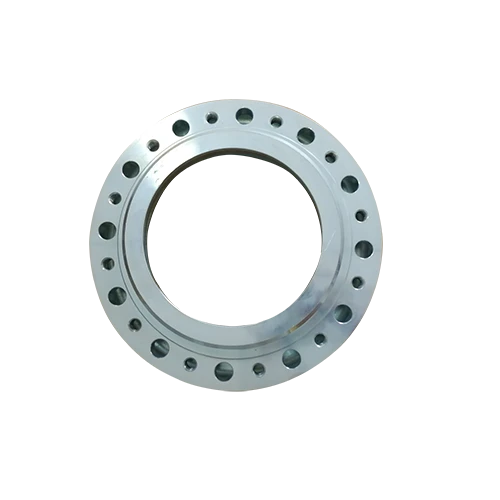

compressor impeller

Operational Functionality

When the compressor starts, the motor spins the impeller at high speeds. This action creates a centrifugal force that draws in air or gas from the inlet port. The rapidly spinning blades impart speed to the incoming fluid, resulting in a velocity increase. As the fluid exits the impeller, it enters the diffuser, where its high kinetic energy is transformed into increased pressure.

The performance of a compressor impeller can be analyzed through parameters such as pressure ratio, flow coefficient, and efficiency. The pressure ratio, defined as the ratio of discharge pressure to inlet pressure, is crucial in determining the effectiveness of the impeller. A higher pressure ratio indicates a more effective impeller design for specific applications.

Applications of Compressor Impellers

Compressor impellers are used widely across various industries. In aviation, they are fundamental components in jet engines, where they compress air before it enters the combustion chamber. In the automotive sector, turbochargers employ impellers to enhance engine efficiency and performance. Additionally, in HVAC systems, these impellers are integral in managing airflow to ensure efficient heating and cooling in residential and commercial buildings.

Challenges and Innovations

Developing advanced compressor impellers is not without challenges. Engineers constantly strive to improve efficiency and reduce noise and emissions, pushing the boundaries of current technology. Innovations such as 3D printing and computational fluid dynamics (CFD) are leading the way in optimizing impeller designs, making them lighter and more efficient than ever before.

Moreover, as industries move towards greener technologies, the emphasis on sustainable materials and designs is gaining traction. This shift not only addresses environmental concerns but also enhances the long-term performance and reliability of compressor impellers.

Conclusion

Compressor impellers are vital components that significantly impact the efficiency and effectiveness of various systems. Their design encompasses complex engineering principles, balancing performance with reliability. As industries evolve and demands increase, continued innovation in compressor impeller technology will be essential for maximizing efficiency and minimizing environmental impact. Understanding the intricacies of these components is crucial for both engineers and stakeholders involved in mechanical and aerospace engineering, ensuring that future systems are equipped with the best possible technology.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025