Mobile:+86-311-808-126-83

Email:info@ydcastings.com

compressor housing in turbocharger

The Role of Compressor Housing in Turbochargers

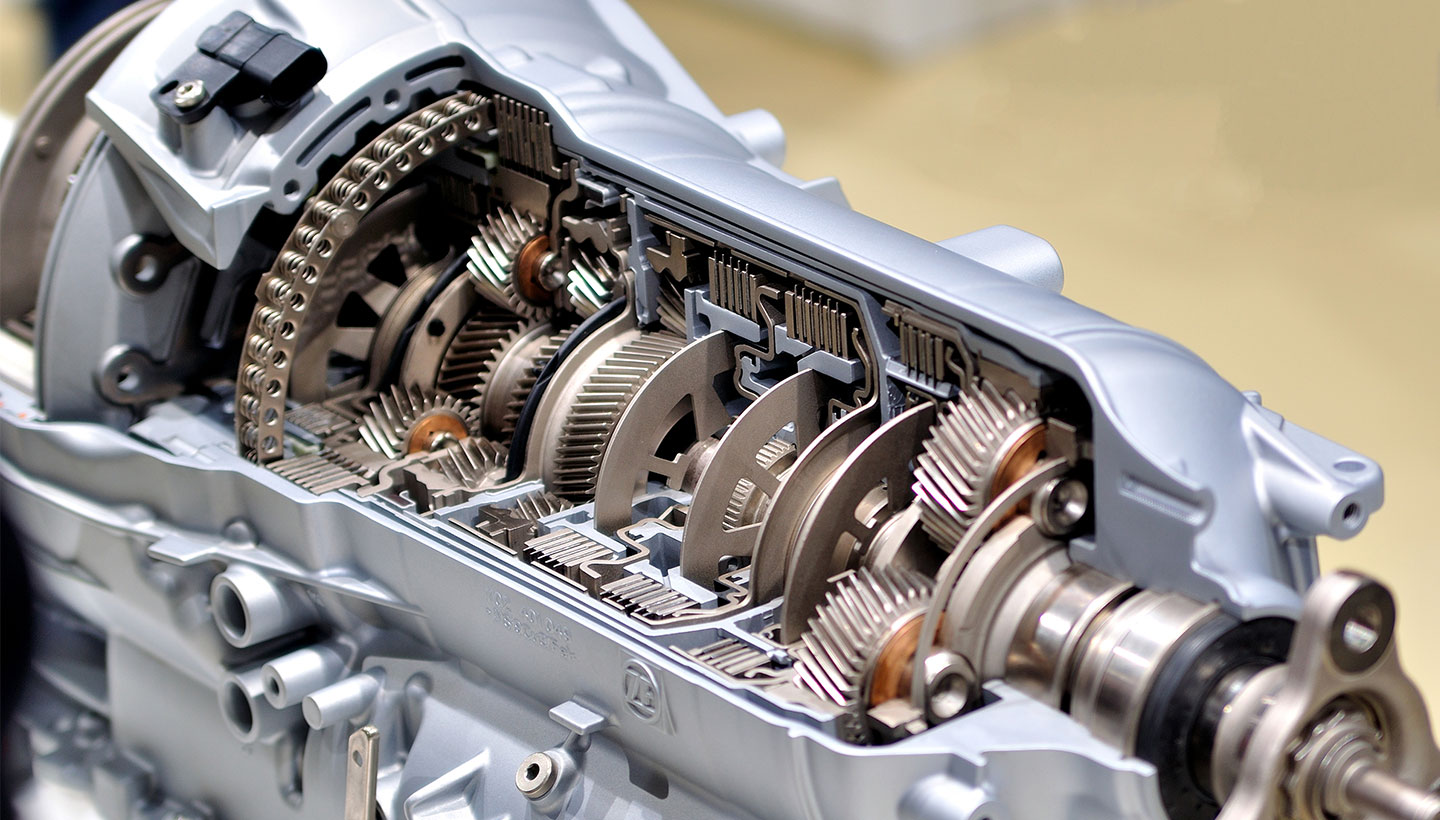

Turbochargers are essential components in modern internal combustion engines, significantly enhancing their performance and efficiency. At the heart of every turbocharger lies the compressor housing, a vital element that plays a pivotal role in the overall functionality of the system. Understanding the compressor housing's design, function, and importance provides insight into how turbochargers work to improve engine performance.

The Role of Compressor Housing in Turbochargers

One of the primary functions of the compressor housing is to streamline airflow into the compressor wheel. The interior design of the housing often features a contour that allows for optimal airflow, minimizing turbulence and pressure losses. This design is crucial because maintaining a smooth flow enhances the compressor's efficiency, allowing the engine to produce more power without an equivalent increase in fuel consumption. Therefore, the geometry of the compressor housing is a focal point in turbocharger design, influencing not only performance but also the overall engine responsiveness.

compressor housing in turbocharger

Additionally, the compressor housing also plays a role in noise reduction. Turbochargers, particularly during rapid acceleration, can create significant noise due to the high-speed rotation of the compressor wheel. Manufacturers often implement sound-dampening features or specific design contours within the housing to mitigate this noise, providing a quieter operation, which is increasingly important for consumer satisfaction in today's automotive market.

Another crucial aspect of the compressor housing is its ability to manage heat. As air is compressed, it heats up, which can lead to decreased efficiency and potential engine knock if not properly managed. Many modern compressor housings are equipped with provisions for intercoolers, which cool the compressed air before it enters the engine. This cooling step not only improves efficiency but also helps in maintaining optimal engine performance by reducing the chances of pre-ignition or knocking due to high temperatures.

Furthermore, advancements in technology have allowed for more flexible designs in compressor housings. Engine manufacturers can tailor the housing shape and size to match the specific demands of the engine configuration and the desired performance characteristics. Innovations in computational fluid dynamics (CFD) have enabled engineers to simulate airflow within the housing, leading to improvements in design that enhance performance metrics and fuel efficiency.

In conclusion, the compressor housing is a significant component in turbocharged engines, directly impacting the performance, efficiency, and overall capabilities of the engine. Its design facilitates optimal airflow, manages heat, enables noise reduction, and allows customization to meet specific engine requirements. As automotive technology continues to evolve, the importance of efficient and well-engineered compressor housings will only grow, affirming their place at the forefront of turbocharger innovation. Understanding this component's role is essential for anyone looking to grasp the complexities of modern automotive engineering.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025