Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Design and Analysis of Compression Fitting End Caps for Enhanced Performance and Durability

Understanding Compression Fitting End Caps A Comprehensive Guide

In various industries such as plumbing, construction, and manufacturing, proper joining methods and tools are essential for creating reliable and efficient systems. One critical component that often comes into play is the compression fitting end cap. While seemingly simple, these end caps play a significant role in maintaining the integrity of a piping system. This article will delve into what compression fitting end caps are, their applications, advantages, and installation process.

What are Compression Fitting End Caps?

Compression fitting end caps are specialized fittings used to seal the end of a pipe, effectively stopping the flow of fluid or gas. They are designed to be attached securely to the pipe using a compression mechanism. This means that as the fitting is tightened, it compresses a ring (or ferrule) against the pipe, creating a tight seal. These fittings are typically made from materials that offer high durability and resistance to corrosion, such as brass, copper, or plastic.

Applications of Compression Fitting End Caps

Compression fitting end caps are used across various sectors. In plumbing systems, they are crucial for capping off pipes that are no longer in use, preventing leaks or the entry of contaminants. In HVAC (Heating, Ventilation, and Air Conditioning) systems, they are used to seal off refrigerant lines, ensuring that the system operates safely and efficiently.

In industrial applications, these end caps are used in process piping systems to isolate sections of the piping network for maintenance or repair without draining the entire system. Their versatility makes them an indispensable component in many scenarios, from residential plumbing to large-scale manufacturing.

Advantages of Compression Fitting End Caps

1. Easy Installation One of the main benefits of compression fitting end caps is their ease of installation. Without the need for welding or soldering, these fittings can be quickly and efficiently secured to pipes, saving time and labor costs.

2. Strong and Reliable Seal When properly installed, compression fittings provide a strong seal that can withstand high pressure and temperature variations. This reliability is crucial in preventing leaks that can lead to costly water damage or system failures.

3. Reusability Unlike permanent fittings, compression fittings can be disassembled and reused, which makes them cost-effective and environmentally friendly. This feature allows for modifications and adjustments without complete replacement.

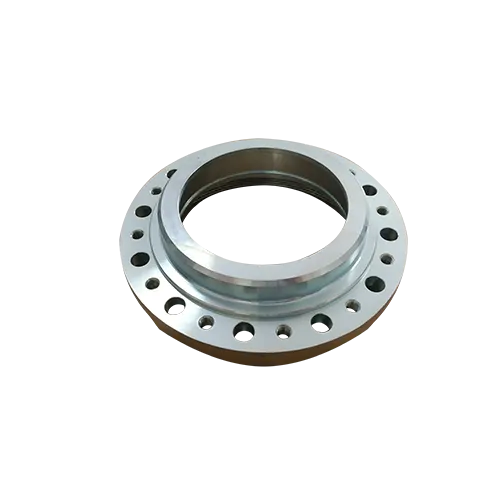

compression fitting end cap

4. Variety of Materials Compression fittings are available in various materials, allowing users to select the most suitable option for their specific application. Whether it’s a corrosive environment or a high-temperature setting, there’s a fitting tailored for the job.

Installation Process

Installing a compression fitting end cap is a straightforward process that involves a few key steps

1. Cut the Pipe Ensure the pipe is cut cleanly and squarely. A proper cut is essential for creating a good seal.

2. Deburr the Edges After cutting, remove any burrs or sharp edges from the pipe to prevent damage to the fitting and ensure a smooth installation.

3. Slide on the Ferrule Before attaching the end cap, slide the ferrule (a small ring) over the end of the pipe.

4. Attach the End Cap Position the end cap over the end of the pipe and press it onto the ferrule. Make sure it is aligned correctly.

5. Tighten the Cap Using a wrench, tighten the end cap carefully. Be cautious not to over-tighten, as this can damage the fitting or the pipe.

6. Check for Leaks Once installed, it’s essential to check for leaks by applying pressure to the system. Any signs of leakage should be addressed immediately.

Conclusion

Compression fitting end caps are vital components for sealing pipes in various applications. Their ease of use, reliable sealing capabilities, and reusability make them a popular choice among professionals. Understanding their functionality and proper installation is crucial for anyone working with piping systems. With the right tools and knowledge, using compression fitting end caps can enhance system safety and efficiency, ensuring that operations run smoothly.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025