Mobile:+86-311-808-126-83

Email:info@ydcastings.com

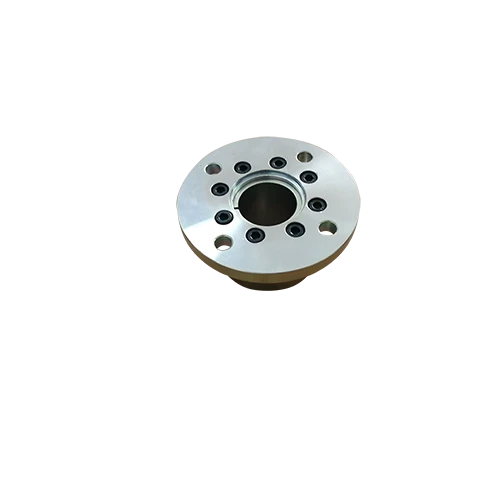

chiller impeller

Understanding Chiller Impeller A Key Component in Refrigeration Systems

Chiller impellers play a crucial role in the efficient operation of refrigeration systems, serving as the heart of chiller units. These components are responsible for the movement of refrigerant or coolant through the system, ensuring optimal heat exchange and maintaining desired temperatures. Understanding the intricacies of chiller impellers, including their design, function, and maintenance, is vital for anyone involved in HVAC or refrigeration technology.

The Role of Chiller Impellers

In refrigeration systems, chillers are used to remove heat from a liquid through a vapor-compression or absorption refrigeration cycle. The impeller, a rotating component of a centrifugal pump, is integral to this process. When the impeller spins, it imparts kinetic energy to the refrigerant, enabling it to flow into the evaporator where heat is absorbed. The design of the impeller affects the efficiency and performance of the entire chiller system.

A well-designed impeller optimizes the flow and pressure of the refrigerant, which is crucial for effective heat exchange. Common materials used for impeller construction include stainless steel, bronze, and various forms of plastic, each selected based on the application, temperature, and pressure conditions.

Design Considerations

The design of chiller impellers varies widely depending on the specific application and operational requirements. Factors such as diameter, blade shape, and number of blades impact performance. For instance, a larger diameter impeller can increase flow rates, while blade shape influences the velocity and efficiency of the coolant movement. The number of blades must also be optimized; too few blades can lead to turbulence, while too many can generate excessive drag.

chiller impeller

Another critical design aspect is the impeller's tolerance. Precision engineering is necessary to ensure that the impeller operates smoothly with minimal wear over time. This precision not only enhances performance but also prolongs the lifespan of the chiller.

Maintenance and Care

Proper maintenance of chiller impellers is essential for efficient system operation. Over time, impellers can become fouled with debris or suffer from erosion due to prolonged exposure to working fluids. Regular inspections should be conducted to identify any wear and tear early on. If damage is detected, proactive measures such as cleaning or replacing the impeller can prevent costly downtimes and inefficiencies.

Additionally, monitoring the operating conditions, like flow rates and pressure levels, can provide insights into the performance of the impeller. Anomalies in these parameters may indicate that the impeller is not functioning correctly, warranting further investigation.

Conclusion

Chiller impellers are fundamental to the performance of refrigeration systems, affecting efficiency, heat transfer, and overall system reliability. Understanding their design, functionality, and maintenance requirements is crucial for engineers, technicians, and anyone involved in HVAC systems. By ensuring that impellers are designed correctly and maintained adequately, the longevity and efficiency of chiller systems can be significantly enhanced, leading to better energy savings and performance in various applications across industries. As technology advances, continued improvements in impeller design and materials will likely drive further enhancements in cooling efficiency and sustainability.