Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Design and Functionality of Volute Casings in Centrifugal Pump Systems

Understanding the Role of Volute Casings in Centrifugal Pumps

Centrifugal pumps are widely used in various industries to transport fluids, utilizing the principles of centrifugal force to create flow. One of the crucial components of a centrifugal pump is the volute casing, which plays a significant role in the efficiency and effectiveness of the pump’s operation. This article explores the design, function, and importance of volute casings in centrifugal pumps.

What is a Volute Casing?

A volute casing is a spiral-shaped shell that surrounds the impeller of a centrifugal pump. The primary purpose of the volute is to convert the kinetic energy generated by the impeller into pressure energy, enabling the pump to move fluids efficiently through pipelines. The design of the volute tapering from a wide inlet to a narrow outlet allows for smooth flow transition and minimizes turbulence.

Design Considerations

The design of a volute casing is critical to the overall performance of a centrifugal pump. Several factors must be considered, including the pump's intended application, the type of fluid being transported, and the operating conditions.

1. Geometry The cross-sectional area of the volute gradually increases in the direction of flow. This design reduces the velocity of the fluid and increases its pressure. The volute's shape influences how well the pump can handle variations in flow rates.

2. Material The choice of material for the volute casing is essential, especially in applications involving corrosive or abrasive fluids. Materials such as stainless steel, cast iron, or specialized alloys may be selected based on the operating environment.

3. Size and Scale The size of the volute must match the size of the impeller and is generally designed to handle the maximum flow rate anticipated for the pump.

Function of the Volute Casing

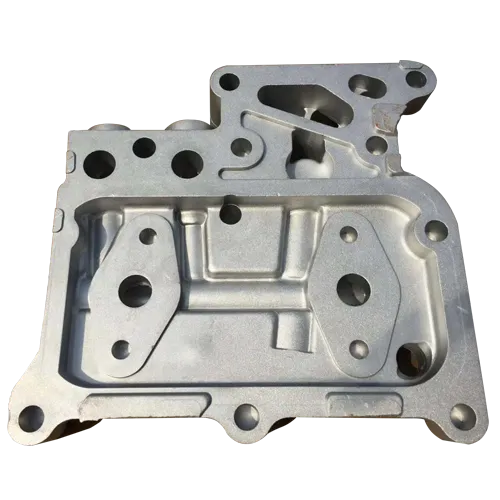

centrifugal pump volute casing

The volute casing serves multiple functions in a centrifugal pump

1. Energy Conversion As the impeller spins, it imparts kinetic energy to the fluid. The volute casing harnesses this energy, converting it into pressure that propels the fluid through the discharge port.

2. Flow Direction The volute casing effectively directs the fluid flow from the impeller to the discharge pipe. Its design ensures that the fluid enters the discharge smoothly, minimizing turbulence and energy loss.

3. Pressure Build-Up By gradually expanding the flow area, the volute helps in building up pressure efficiently, which is essential for moving fluids across distances in pipelines.

4. Vibration and Noise Reduction Properly designed volute casings can also help in reducing vibrations and noise generated during pump operation, enhancing the overall experience for users.

Importance of the Volute Casing

The volute casing is integral to the performance and reliability of centrifugal pumps. An optimized volute design can lead to increased efficiency, reduced energy consumption, and longer operational life for the pump. Poorly designed volute casings can result in issues such as cavitation, increased wear, and decreased flow rates, ultimately leading to higher maintenance costs and reduced pump life.

In applications where precise flow control is essential, the volute’s characteristics can greatly impact the pump's ability to maintain target performance levels. Industries ranging from water supply to chemical processing heavily rely on the efficient design and operation of the volute casing within centrifugal pumps.

Conclusion

In summary, the volute casing is a vital component of centrifugal pumps that enhances their efficiency and functionality. With careful consideration given to design, material selection, and operational conditions, volutes can significantly improve pump performance, making them indispensable in myriad industrial applications. As technology progresses, innovative volute designs and materials continue to evolve, ensuring that centrifugal pumps remain essential tools for fluid handling in various sectors.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025