Mobile:+86-311-808-126-83

Email:info@ydcastings.com

40mm Blanking Cap for Efficient Sealing Solutions and Applications

Understanding the Importance of Blanking Caps A Focus on 40mm Variants

In various industries, the use of blanking caps plays a critical role in the efficient and safe functioning of systems. Specifically, the 40mm blanking cap is an essential component that caters to numerous applications, ensuring the protection and integrity of pipe systems, containers, and equipment. This article explores the significance of these caps, their characteristics, benefits, and applications.

What is a Blanking Cap?

A blanking cap is a device designed to seal off the end of a pipe or fitting. These caps are essential in preventing the entry of debris, moisture, and other contaminants that can compromise the quality and safety of the system. They are also vital for maintaining pressure within a system and ensuring that any residual materials do not escape. The 40mm blanking cap, in particular, is a widely used size due to its versatility in various applications.

Key Characteristics of 40mm Blanking Caps

40mm blanking caps are typically made from durable materials such as PVC, metal, or rubber, depending on the specific needs of the application. These caps are designed to provide a snug fit on pipes or fittings of the same diameter. The choice of material is crucial as it determines the cap's resistance to temperature fluctuations, chemical exposure, and mechanical stress.

Moreover, many 40mm blanking caps come with features such as threaded or smooth edges, allowing for easy installation and removal. Some may also include additional sealing components to enhance airtightness and prevent leaks.

Benefits of Using 40mm Blanking Caps

1. Protection Against Contaminants The primary function of a blanking cap is to shield the system from external contaminants, thereby maintaining the internal environment's integrity.

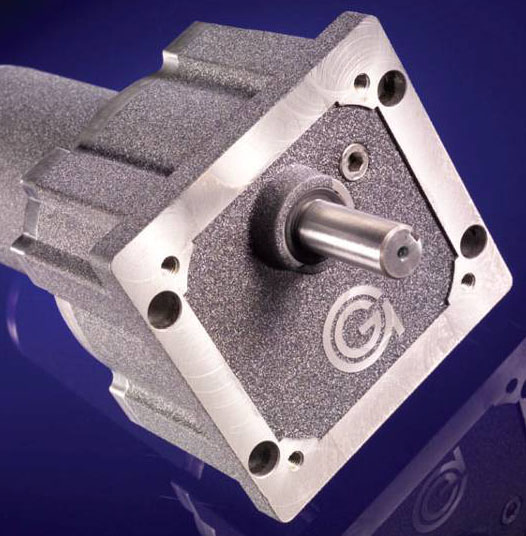

blanking cap 40mm

2. Pressure Maintenance These caps help retain the necessary pressure within pipes or vessels, ensuring efficient operation and performance.

3. Safety By preventing accidental spills or leaks, blanking caps contribute to a safer working environment, minimizing the risk of accidents.

4. Cost-Effectiveness The use of blanking caps can lead to significant cost savings by reducing the need for maintenance and repairs. By protecting systems from potential damage, they help avoid costly downtimes.

5. Versatility The 40mm size makes these caps suitable for a wide range of applications, from plumbing and HVAC systems to automotive and industrial equipment.

Applications of 40mm Blanking Caps

The versatility of 40mm blanking caps means they are used across various sectors. In the plumbing industry, they are crucial for sealing off unused pipes and creating temporary closures for maintenance work. In the automotive sector, these caps prevent fluid leaks and protect engine components from dirt and moisture.

Additionally, in manufacturing and chemical processing, blanking caps play a vital role in ensuring that systems operate smoothly and without contamination. In laboratories, they are used to seal containers, preventing spillage and ensuring accurate measurements.

Conclusion

In conclusion, 40mm blanking caps are integral components that serve a multitude of purposes in diverse industries. Their ability to protect against contaminants, maintain pressure, and ensure safety makes them indispensable in modern practices. As technology evolves and industries become more demanding, the importance of reliable sealing solutions like the 40mm blanking cap cannot be overstated. Understanding their application and benefits is essential for professionals seeking to ensure the longevity and efficiency of their systems.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025