Mobile:+86-311-808-126-83

Email:info@ydcastings.com

axial flow impeller

Understanding Axial Flow Impellers

Axial flow impellers are crucial components in various industrial applications, particularly in mixing, pumping, and aeration processes. These devices excel at moving fluids along the axis of rotation, making them an essential choice for tasks requiring efficient fluid handling and mixing.

Design and Functionality

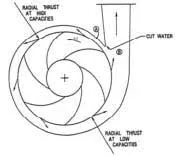

The primary function of an axial flow impeller is to impart kinetic energy to the fluid, creating a flow that parallels the impeller's rotational axis. The design typically consists of blades that are angled to generate lift as the impeller rotates. This design allows the fluid to flow in a straight path, which is particularly effective for applications that demand high flow rates and low-pressure increases.

In comparison to other types of impellers, such as radial flow impellers, axial flow impellers offer unique advantages. They are particularly suited for operations involving low-viscosity fluids where high flow rates are needed. For instance, they are commonly found in applications such as chemical processing, water treatment, and even food and beverage industries.

Applications

The versatility of axial flow impellers stems from their ability to adjust to different operational needs. In wastewater treatment plants, for example, these impellers facilitate the mixing of wastewater with treatment chemicals, promoting effective treatment. In the chemical industry, they are used to ensure homogeneous mixing of reactants, enhancing reaction efficiency.

Moreover, axial flow impellers are extensively utilized in marine applications, such as in ship propulsion systems

. Their ability to generate thrust by efficiently moving water parallel to the direction of the ship is critical for navigation and speed control.

axial flow impeller

Advantages

One of the principal advantages of axial flow impellers is their capacity to handle large volumes of fluid efficiently. They are designed to operate at a high speed, which allows for significant fluid movement without a substantial increase in pressure. This low-pressure operation is crucial in processes where maintaining the integrity of delicate materials is essential.

Additionally, axial flow impellers tend to have a more straightforward design, which can lead to easier maintenance and lower manufacturing costs. Their efficient energy usage also translates into lower operational costs, further enhancing their appeal in industrial settings.

Challenges

Despite their numerous advantages, axial flow impellers also face challenges. They can be susceptible to cavitation, especially in situations where the pressure drops below the vapor pressure of the fluid, leading to potential damage and reduced efficiency. Moreover, careful consideration must be given to the blade design and operating conditions to optimize performance and prevent issues such as excessive wear or fluid turbulence.

Conclusion

In conclusion, axial flow impellers are invaluable in numerous industries, offering efficient fluid movement, ease of maintenance, and cost-effectiveness. With their unique design and capabilities, they continue to play a vital role in processes that demand high throughput and effective fluid management. As technology advances, the design and efficiency of axial flow impellers will likely evolve, further enhancing their importance in industrial applications.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025