Mobile:+86-311-808-126-83

Email:info@ydcastings.com

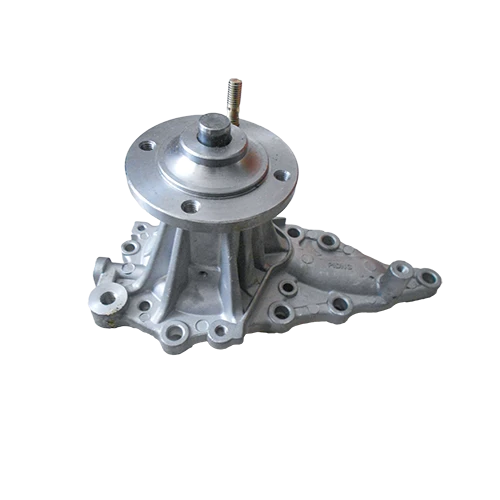

aluminum casting manufacturers

The Growing Industry of Aluminum Casting Manufacturers

In recent years, the aluminum casting industry has witnessed significant growth, driven by advancements in technology, increasing demand from various sectors, and the inherent properties of aluminum itself. Aluminum casting manufacturers play a crucial role in producing lightweight, strong, and corrosion-resistant components that cater to a range of industries, from automotive and aerospace to consumer goods and electronics.

One of the primary reasons for the rising popularity of aluminum casting is the material's favorable characteristics. Aluminum is well-known for its lightweight nature, making it an ideal choice for applications where reducing weight is essential, such as in vehicle manufacturing. Lighter vehicles can lead to better fuel efficiency, which is a critical factor in today’s environmentally-conscious market. Moreover, aluminum exhibits excellent strength-to-weight ratios, ensuring that cast products are both durable and efficient.

The aluminum casting process itself has evolved significantly over the years. Traditional sand casting methods have been enhanced with modern techniques like die casting and investment casting, which provide higher precision and better surface finishes. These advancements allow manufacturers to produce intricate designs that were previously difficult to achieve. As industries continue to push for innovation in design and performance, aluminum casting manufacturers must stay ahead by investing in the latest technologies and equipment.

aluminum casting manufacturers

Moreover, the global trend towards sustainability and the circular economy has further influenced the aluminum casting market. Aluminum can be recycled multiple times without losing its properties, making it an environmentally-friendly choice for manufacturers. Many companies are now focusing on sourcing recycled aluminum, significantly reducing their carbon footprint and promoting sustainable production practices. This shift not only benefits the environment but also aligns with the growing consumer demand for eco-friendly products.

In addition to sustainability, the aluminum casting market is buoyed by the automotive sector's ongoing transformation. With the rise of electric vehicles (EVs) and the push for more fuel-efficient models, aluminum is becoming the preferred material for many automotive components. Manufacturers are developing specialized casting techniques to create lightweight parts that contribute to the overall efficiency of EVs, thereby positioning themselves as leaders in this rapidly evolving market.

Furthermore, aluminum casting manufacturers are increasingly adopting digital technologies, such as computer-aided design (CAD) and simulation software, to enhance their production processes. These tools enable manufacturers to optimize designs before casting, reducing waste and improving cost efficiency. The integration of Industry 4.0 principles, such as automation and data analytics, is also allowing manufacturers to streamline operations, leading to faster turnaround times and improved product quality.

In conclusion, the aluminum casting industry is poised for continued growth as manufacturers adapt to emerging trends in technology, sustainability, and market demands. The versatility of aluminum, combined with modern casting techniques and a focus on eco-friendliness, positions aluminum casting manufacturers as key players in the quest for innovative and sustainable solutions across various industries. As the demand for high-quality aluminum components rises, these manufacturers will undoubtedly shape the future of production in a multitude of sectors.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025