Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Aluminum Die Casting Techniques and Applications for Efficient Manufacturing Solutions

Aluminum Casting Die A Key Element in Manufacturing

Aluminum casting is a vital process in manufacturing that involves pouring molten aluminum into a mold to create intricate shapes. One of the pivotal components of this process is the aluminum casting die, which is essentially the mold used to shape the aluminum. The role of casting dies in aluminum casting cannot be overstated, as they significantly influence the quality, efficiency, and cost-effectiveness of the final product.

Aluminum is a preferred metal for casting due to its lightweight nature, corrosion resistance, and excellent thermal and electrical conductivity. Moreover, its relatively low melting point allows for easier processing compared to other metals. However, the effectiveness of aluminum casting largely depends on the design and quality of the casting die.

Types of Aluminum Casting Dies

There are several types of aluminum casting dies, depending on the specific requirements of the manufacturing process. The most common types include permanent molds, sand molds, and investment molds.

1. Permanent Molds These are typically made from steel or iron and designed for high-volume production. The use of permanent molds allows for better dimensional accuracy and surface finish, making them ideal for producing complex shapes in larger quantities. They are reusable and can withstand the heat of molten aluminum, making them economical in the long run.

2. Sand Molds Sand casting is one of the oldest and most versatile methods of casting. In this process, a mixture of sand and a binding agent is used to form the mold. Sand molds are suitable for low to medium production volumes and offer greater flexibility in mold design. However, they may not achieve the same level of accuracy and surface finish as permanent molds.

3. Investment Molds Also known as lost-wax casting, this method involves creating a wax pattern coated with a ceramic material. Once the ceramic sets, the wax is melted away, leaving a precise mold for aluminum casting. This method allows for exceptionally high accuracy and is often used for intricate designs and prototypes.

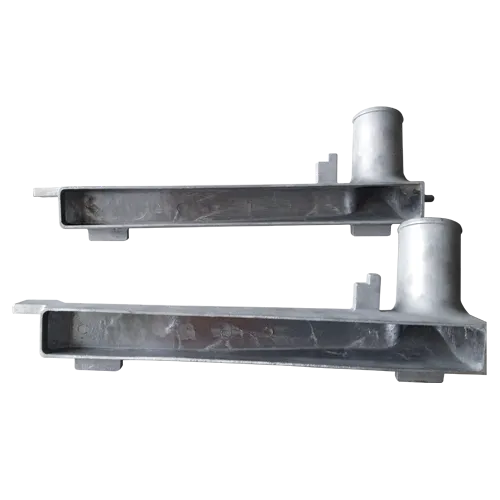

aluminum casting die

The Design Considerations for Casting Dies

Designing an aluminum casting die requires meticulous attention to detail. Engineers and designers must ensure that the die can withstand the thermal and mechanical stresses imposed during the casting process. Factors such as wall thickness, draft angles, and ribbing must be carefully considered to facilitate easy demolding and reduce the risk of defects.

Additionally, the die’s surface finish is crucial as it directly impacts the surface quality of the cast aluminum parts. A well-finished die will enhance the aesthetic appeal of the final product while reducing the need for additional machining or finishing processes.

The Impact of Technology on Aluminum Casting Dies

Recent advancements in technology have revolutionized the design and production of aluminum casting dies. Computer-aided design (CAD) and computer-aided engineering (CAE) tools enable designers to simulate the casting process, helping to identify potential issues before production begins. Moreover, additive manufacturing (3D printing) is gaining traction in producing complex die geometries that were previously challenging or impossible to achieve using traditional methods.

The incorporation of these technologies not only improves the accuracy and efficiency of casting dies but also reduces production lead times and costs. This is particularly beneficial in industries where time-to-market is critical.

Conclusion

In conclusion, aluminum casting dies play a central role in the manufacturing of aluminum components. The choice of die type, design considerations, and the integration of new technologies are all instrumental in ensuring high-quality casting results. As industries continue to evolve, the importance of innovation in aluminum casting die manufacturing will remain paramount, driving efficiency and quality in an increasingly competitive market. With the right processes in place, manufacturers can harness the full potential of aluminum casting, leading to a wide range of applications across various sectors, from automotive to aerospace and beyond.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025