Mobile:+86-311-808-126-83

Email:info@ydcastings.com

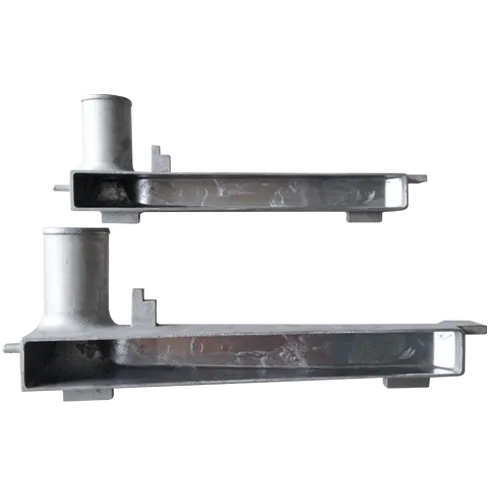

aluminium gravity die casting

Aluminium Gravity Die Casting A Comprehensive Overview

Aluminium gravity die casting is a highly effective manufacturing process that has gained significant traction in various industries, owing to its ability to produce complex shapes with high dimensional accuracy and excellent surface finish. This method leverages gravity to fill the die with molten aluminium, allowing the material to solidify into the desired form. As industries increasingly demand lightweight and durable components, aluminium gravity die casting has emerged as a preferred choice for manufacturers.

The Process

The aluminium gravity die casting process begins with the preparation of the die, which is usually made from high-quality steel. The die consists of two halves that are carefully machined to create the desired shape of the part. Once the die is prepared, it is coated with a release agent to facilitate the easy removal of the casting once it solidifies.

Next, aluminium alloy is melted in a furnace, typically at temperatures around 660°C (1220°F). The molten aluminium is then poured into the preheated die, relying on gravitational force to fill the cavity. Unlike other casting methods that employ pressure, gravity die casting allows the molten metal to flow naturally, which minimizes inclusions and enhances the metal's mechanical properties.

After the die is filled, the aluminium cools and solidifies rapidly, thanks to the conductive properties of the steel die. Once the casting process is complete, the die is opened, and the casting is removed. This process can be repeated multiple times, making it an efficient method for mass production.

Advantages of Aluminium Gravity Die Casting

1. High Dimensional Accuracy One of the most significant advantages of this method is its ability to produce parts with tight tolerances. This accuracy is crucial in industries such as automotive and aerospace, where precision is paramount.

2. Excellent Surface Finish The gravity die casting process yields a smooth surface finish, reducing the need for extensive machining or finishing work. This not only saves time and costs but also enhances the aesthetic appeal of the final product.

3. Material Efficiency The process minimizes waste material, as the die can be reused multiple times, leading to lower overall material costs. Furthermore, aluminium itself is a recyclable material, contributing to sustainability.

aluminium gravity die casting

4. Versatility Aluminium gravity die casting can accommodate a wide range of shapes and sizes, making it suitable for various applications, from small components to large structural parts. This versatility allows manufacturers to tailor products to meet specific needs.

5. Enhanced Mechanical Properties Cast parts made from aluminium alloys exhibit excellent strength-to-weight ratios, corrosion resistance, and durability. As a result, products cast through this method are ideal for demanding environments.

Applications

Aluminium gravity die casting is widely used in numerous industries. In the automotive sector, it's employed to manufacture engine blocks, transmission cases, and various components that require lightweight properties without compromising strength. The aerospace industry also benefits from this casting method for producing parts where weight savings can translate to enhanced fuel efficiency.

Other applications include the production of consumer goods, industrial machinery, and electronic housings. The ability to create intricate designs while maintaining robustness makes aluminium gravity die casting a sought-after solution across diverse fields.

Challenges and Considerations

While aluminium gravity die casting is advantageous, it is not without challenges. The initial costs of die creation can be substantial, particularly for complex designs. Moreover, maintaining the quality of the molten aluminium is crucial, as contamination can lead to defects in the final product. Companies must also consider the thermal conductivity of the die, as uneven cooling can affect the overall quality of the casting.

Conclusion

Aluminium gravity die casting stands out as a sophisticated manufacturing process that aligns with the evolving demands of modern industries. With its blend of precision, efficiency, and the ability to produce durable components, this method continues to play a vital role in the production of high-quality aluminium parts. As technology advances and sustainability becomes increasingly important, the role of aluminium gravity die casting is likely to expand, providing innovative solutions for manufacturers worldwide.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025