Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Heat Treatment Processes for Enhancing Aluminium Casting Properties and Performance

Understanding Aluminum Casting Heat Treatment

Aluminum casting is a widely used process in the manufacturing industry, renowned for its lightweight properties, excellent corrosion resistance, and ability to be molded into complex shapes. However, the performance and mechanical characteristics of aluminum castings can be significantly improved through an effective heat treatment process. This article delves into the various aspects of aluminum casting heat treatment, including its purpose, methods, and benefits.

Purpose of Heat Treatment

Heat treatment is a critical process aimed at altering the physical and sometimes chemical properties of a material. For aluminum castings, the primary goals are to enhance strength, improve ductility, relieve internal stresses, and refine microstructural features. The right heat treatment can transform as-cast aluminum into a material suitable for high-performance applications, such as in the automotive or aerospace industries.

Methods of Heat Treatment

1. Solution Treatment The first step in the heat treatment process is solution treatment, which involves heating the aluminum casting to a temperature where alloying elements dissolve into the aluminum matrix. Typically, this temperature ranges between 480°C and 550°C, depending on the specific alloy. The casting is held at this temperature for a predetermined time, allowing the alloying elements to fully diffuse into the aluminum solution. This phase is crucial, as it sets the stage for further strengthening through aging.

2. Quenching Following solution treatment, the aluminum casting is rapidly cooled by quenching it in water or oil. This rapid cooling ‘locks’ the dissolved elements in a supersaturated solid solution, preventing them from precipitating out during cooling. Quenching must be done carefully to avoid sudden thermal stresses that can cause warping or cracking.

3. Aging After quenching, the component undergoes aging, which can be natural or artificial. In natural aging, the casting is left at room temperature for an extended period, allowing the supersaturated solution to precipitate out and form fine particles that strengthen the alloy. In artificial aging, the casting is reheated to a specific temperature, usually between 150°C and 200°C, for a shorter duration. This controlled heating accelerates the precipitation process, resulting in more significant strength improvements in a much shorter timeframe.

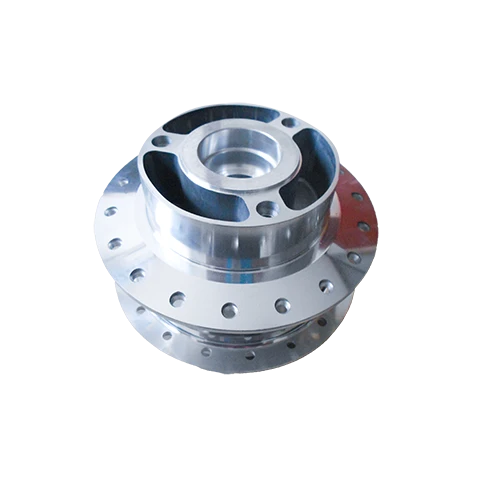

aluminium casting heat treatment

Benefits of Heat Treatment

The benefits of heat treating aluminum castings are manifold

- Increased Strength One of the most significant advantages is the substantial increase in mechanical strength. Heat-treated aluminum can achieve yield strengths that are several times higher than those of the as-cast material, making it more suitable for load-bearing applications.

- Enhanced Ductility Alongside increased strength, heat treatment improves the ductility of aluminum castings. This means that the material can be deformed without fracturing, making it more versatile for applications requiring complex geometries and shapes.

- Stress Relief The heat treatment process helps in relieving internal stresses that develop during the casting process. This ensures dimensional stability and reduces the risk of distortion or failure during further processing or in service.

- Improved Corrosion Resistance Some heat-treated aluminum alloys exhibit enhanced resistance to corrosion, especially when exposed to harsh environments. This makes them suitable for various applications, including marine and automotive contexts.

Conclusion

In conclusion, heat treatment is an essential process for enhancing the properties of aluminum castings. By employing methods such as solution treatment, quenching, and aging, manufacturers can significantly improve the strength, ductility, and overall performance of aluminum components. As industries continue to demand lightweight, high-performance materials, understanding and effectively implementing heat treatment processes will remain a key factor in advancing aluminum casting applications. Whether for aerospace engineering or automotive manufacturing, the careful consideration of heat treatment can lead to innovations that push the boundaries of material performance and application.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025