Mobile:+86-311-808-126-83

Email:info@ydcastings.com

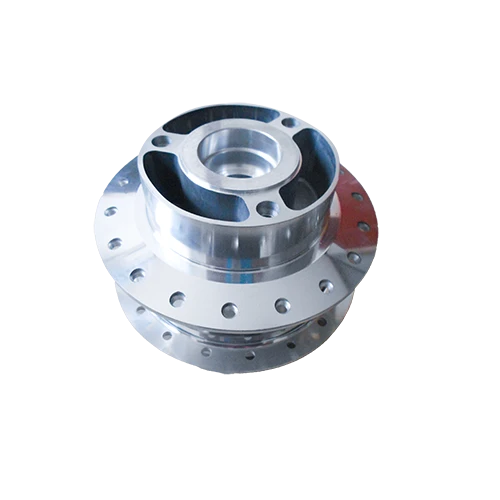

60mm blanking cap

The Importance of 60mm Blanking Caps in Industrial Applications

In the realm of industrial manufacturing, the significance of tiny components can often be overlooked. Among these vital elements are blanking caps, particularly the 60mm variety. These caps play a crucial role in various applications, ensuring efficiency, safety, and reliability throughout production processes. This article delves into the importance, applications, and benefits of using 60mm blanking caps in different industries.

What is a Blanking Cap?

A blanking cap is a component designed to seal or close off the end of a pipe, tube, or fitting. They are essential when a portion of a system is not in use, helping to prevent debris from entering and ensuring the integrity of the system. The 60mm blanking cap specifically refers to caps with a diameter of 60 millimeters, commonly utilized in plumbing, automotive, and manufacturing applications.

Versatility Across Industries

One of the standout features of 60mm blanking caps is their versatility. In plumbing, for example, these caps are used to block off unused pipe ends, maintaining a clean and functional system. They can also be critical in the automotive industry, where they help seal fuel or fluid lines during maintenance or repair work. Furthermore, in manufacturing settings, these caps can be employed in assembly lines to temporarily close off ports while parts are being processed, ensuring that no contaminants interfere with production quality.

Benefits of Using 60mm Blanking Caps

60mm blanking cap

1. Protection Against Contaminants One of the primary functions of a blanking cap is to protect open ends from dirt, dust, debris, and moisture. By sealing these open ends, manufacturers can maintain the cleanliness and integrity of fluid systems, significantly reducing the risk of contamination.

2. Enhanced Safety Open pipes or tubes in industrial settings can pose safety hazards. They can lead to leaks, spills, or accidental injuries. The use of 60mm blanking caps eliminates these risks by ensuring that no materials can escape and that no foreign objects can enter the system.

3. Cost-Effective Solution Investing in blanking caps, such as the 60mm variety, is often more cost-effective than dealing with the consequences of contamination or accidents caused by open pipes. Regular maintenance and repairs can be significantly reduced by proactively using blanking caps.

4. Easy Installation and Removal 60mm blanking caps are designed for ease of use. Their installation and removal processes are straightforward, allowing for quick adjustments in various settings. This is particularly beneficial in fast-paced environments where efficiency is critical.

5. Durability and Reliability Typically made from robust materials such as plastic or metal, 60mm blanking caps are designed to withstand harsh chemical environments and extreme temperatures. Their durability ensures that they remain functional over long periods, providing reliable performance in challenging conditions.

Conclusion

In conclusion, while they may appear to be simple components, 60mm blanking caps serve essential functions across a wide range of industries. Their ability to protect against contaminants, enhance safety, and provide a cost-effective solution makes them indispensable in various applications. As industries continue to evolve and prioritize efficiency, the role of components like blanking caps will only become more significant. Investing in quality blanking caps can lead to improved operational integrity, ultimately driving success in manufacturing and other industrial processes. In a world where every detail counts, the importance of seemingly minor components like the 60mm blanking cap cannot be overstated.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025