Mobile:+86-311-808-126-83

Email:info@ydcastings.com

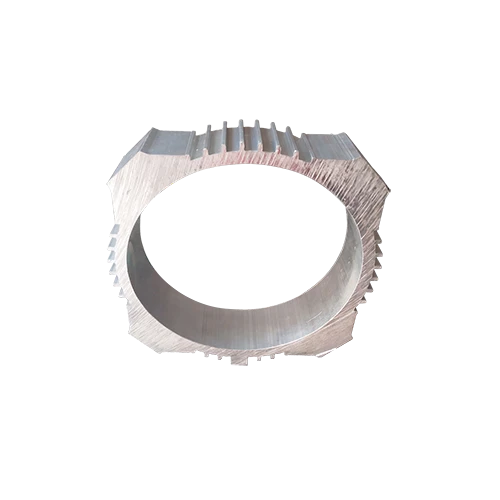

3d print aluminum casting

The Future of Manufacturing 3D Print Aluminum Casting

In recent years, the manufacturing landscape has been transformed by advancements in 3D printing technology, particularly in the realm of metal casting. Among various metals, aluminum has gained significant traction due to its favorable properties, including lightweight, high strength-to-weight ratio, excellent corrosion resistance, and thermal conductivity. This article explores the synergy between 3D printing and aluminum casting, highlighting its implications for various industries.

Understanding 3D Printing and Aluminum Casting

3D printing, also known as additive manufacturing, involves creating objects layer by layer from digital models. This process contrasts sharply with traditional subtractive manufacturing methods, which cut away material to achieve the desired shape. Aluminum casting, on the other hand, typically involves pouring molten aluminum into a mold, allowing it to solidify and take shape.

The integration of 3D printing with aluminum casting opens new avenues for innovation. The capabilities of 3D printing allow for the creation of complex geometries that would be virtually impossible or prohibitively expensive to achieve using traditional methods. Additionally, it significantly reduces material waste, a critical factor in sustainable manufacturing.

Benefits of 3D Printed Aluminum Castings

1. Design Flexibility One of the primary advantages of 3D printed aluminum casting is the design flexibility it offers. Engineers and designers can create intricate shapes and structures that optimize performance, weight, and functionality. This is especially valuable in industries such as aerospace and automotive, where even minor weight reductions can lead to substantial fuel savings.

2. Rapid Prototyping The ability to quickly produce aluminum castings allows companies to accelerate their prototyping process. Businesses can test and iterate designs at a fraction of the time and cost involved in traditional casting methods. This agility enables manufacturers to respond swiftly to market demands and technological advancements.

3d print aluminum casting

3. Reduced Lead Times Traditional aluminum casting often involves lengthy lead times associated with mold creation and preparation. In contrast, 3D printing eliminates the need for complex mold-making processes, significantly reducing lead times. This advantage is crucial in industries where speed to market is a competitive necessity.

4. Cost Efficiency While the initial setup costs for 3D printing technologies may be higher, the long-term savings can be substantial. By minimizing material waste and reducing labor and production costs, companies can achieve a more cost-effective manufacturing process over time.

5. Customization 3D printing allows for one-off custom designs without the need for expensive molds or tooling changes. This capability is particularly beneficial in industries requiring bespoke components, such as medical devices and specialized machinery.

Challenges and Future Perspectives

Despite its numerous benefits, the combination of 3D printing and aluminum casting is not without challenges. Issues such as material limits, surface finish quality, and post-processing requirements pose hurdles that must be addressed to enhance the efficiency of this manufacturing process. Furthermore, industry standards and regulations surrounding additive manufacturing are still evolving.

Looking ahead, the future of 3D printed aluminum casting appears promising. Ongoing research and technological advancements are likely to mitigate current limitations, making the process more accessible and practical for a wider range of applications. As more companies adopt these technologies, we may witness a significant shift in how products are designed and manufactured, paving the way for a more sustainable and efficient industry.

Conclusion

3D printed aluminum casting represents a significant leap forward in manufacturing capabilities. With its benefits of design flexibility, rapid prototyping, reduced lead times, cost efficiency, and customization, it is transforming the way industries approach production. As technology continues to evolve, it is poised to redefine the standards of manufacturing, ushering in a new era of innovation and sustainability. The possibilities are endless, and the journey has just begun.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025