Mobile:+86-311-808-126-83

Email:info@ydcastings.com

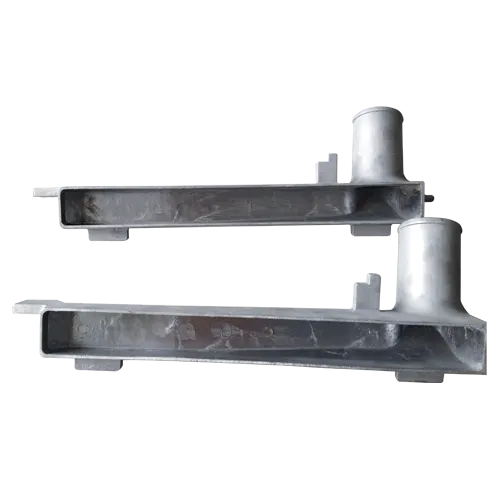

3 inch 204 threaded cap for versatile applications in plumbing and construction

Understanding the 3% 204 Inch Threaded Cap Applications and Benefits

In the world of piping and plumbing, the components used play a critical role in ensuring the efficient and safe transport of fluids. One such essential component is the threaded cap, and specifically, the 3% 204 inch threaded cap. This article delves into the features, applications, and benefits of this specific type of threaded cap.

What is a Threaded Cap?

A threaded cap is a closure device used in piping systems to seal the open ends of pipes or fittings. The internal threading allows for a secure connection, which helps prevent leaks and maintains the integrity of the system. Threaded caps come in various sizes, materials, and designs, and they are essential in a variety of applications, from industrial settings to everyday household plumbing.

Features of the 3% 204 Inch Threaded Cap

The 3% 204 inch designation typically refers to the size specification of the cap, which is average yet versatile. The 3% may denote a specific attribute, such as an interesting feature or a material property, while 204 inch emphasizes the diameter measurement in inches. This size is particularly handy in systems where space is limited yet the need for secure containment is vital.

Common materials for threaded caps include plastic, brass, and stainless steel. Each material has its own set of properties that make it suitable for certain environments. For instance, stainless steel is known for its durability and resistance to corrosion, making it ideal for use in chemical processing and marine applications. Plastic caps might be more appropriate in applications involving less demanding conditions.

Applications of the 3% 204 Inch Threaded Cap

The 3% 204 inch threaded cap finds applications across various industries

1. Plumbing In residential and commercial plumbing systems, threaded caps are extensively used to seal off pipes that are not currently in use, allowing for easy modifications or repairs without the need for complete system replacements. 2. Petrochemical Industry These caps facilitate the secure closure of tanks and pipelines, preventing leakage and environmental contamination. Given the highly volatile nature of the materials involved, a reliable cap is essential.

3 4 inch threaded cap

3. Water Supply Systems In municipal and private water supply systems, threaded caps are crucial for the maintenance and testing of water pipelines, ensuring that they can be tested for pressure and integrity without leaks.

4. Food and Beverage In this industry, maintaining hygiene and preventing contamination is critical. Threaded caps made from food-safe materials can secure packaging and containers effectively.

Benefits of Using the 3% 204 Inch Threaded Cap

Utilizing a 3% 204 inch threaded cap provides several advantages

- Leak Prevention The threaded design ensures a snug fit, significantly reducing the risk of leaks.

- Ease of Installation The simple design makes these caps easy to install and remove, facilitating maintenance and modifications to the plumbing system without complicated tools.

- Versatility With various material options available, the 3% 204 inch threaded cap can be used in multiple applications, from standard plumbing to more specialized industrial usages.

- Cost-Effectiveness By preventing leaks, these caps can ultimately save money on water bills and maintenance costs, as well as prevent costly environmental clean-ups.

Conclusion

The 3% 204 inch threaded cap is not just a small component; it plays a significant role in ensuring the functionality and safety of various piping systems. Whether in plumbing, petrochemical, or food and beverage applications, its ability to provide a secure seal makes it a valuable asset in any fluid transport system. By understanding its features, applications, and benefits, industries can better appreciate the importance of such seemingly small components in the larger picture of fluid management.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025