Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimizing Pump Performance with 12 Percent Impeller Efficiency for Enhanced Fluid Dynamics

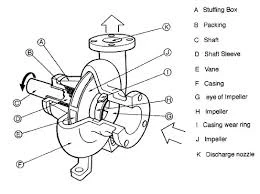

Understanding the 12% Impeller A Key Component in Fluid Dynamics

The 12% impeller is a crucial element in various fluid dynamics applications, particularly in pumps and compressors. Its design is tailored to optimize the performance of fluid movement, delivering efficient energy transfer and maximizing flow rates. Understanding the functionality and significance of the 12% impeller is essential for engineers and technicians working within pump systems.

Understanding the 12% Impeller A Key Component in Fluid Dynamics

One of the key advantages of a 12% impeller is its ability to manage varying fluid capacities effectively. When properly designed, it can maintain high performance across a range of operational conditions, such as changes in fluid viscosity or flow resistance. This versatility makes it suitable for various industries, from municipal water supply and wastewater treatment to chemical processing and HVAC systems.

12 impeller

The efficiency of an impeller directly correlates with its design. A 12% impeller is usually designed with optimal blade angles and shapes to enhance fluid entrainment and minimize energy loss. In practical terms, this means that an impeller of this design can move a greater volume of fluid for a given amount of energy input, which is crucial for reducing operational costs and improving sustainability in industrial processes.

Moreover, the 12% impeller’s ability to handle solids within the fluid stream is a significant consideration in its design. Many applications require the movement of not just liquids but also slurries containing particulate matter. A well-designed 12% impeller can prevent clogging and reduce wear and tear, ensuring prolonged service life and reliability within a system.

In summary, the 12% impeller represents a sophisticated and efficient solution in fluid dynamics applications. Its unique design characteristics enable it to perform effectively across various conditions, providing vital benefits such as enhanced flow rates, energy efficiency, and reliable operation even in challenging environments. As industries continue to evolve, the importance of optimizing component design like the 12% impeller will only grow, making it an enduring focus for engineers and manufacturers alike.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025