Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Italian

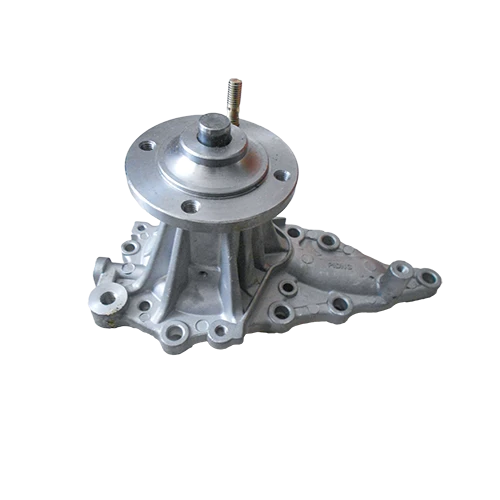

Vortex Casing Pump - High Efficiency and Reliable Performance

Understanding Vortex Casing Pumps Principles and Applications

A vortex casing pump is a specialized type of centrifugal pump designed to efficiently handle fluids with a high solid content and those that are prone to clogging. Its unique design, featuring a vortex impeller, allows for the effective movement of fluids while minimizing turbulence and wear on the pump components. This article delves into the principles behind vortex casing pumps, their operational mechanisms, advantages, and typical applications.

Working Principle

At the heart of the vortex casing pump is its distinctive impeller design. The vortex impeller creates a whirlpool effect, generating a rotating flow of liquid that separates solid particles from the primary fluid. The fluid enters the pump through an inlet, where it is directed into the impeller's vanes. As the impeller rotates, it propels the fluid outward, creating a low-pressure zone at the center. This action allows the solids to be carried along in a vortex motion, preventing them from settling and blocking the flow.

One of the key features of a vortex casing pump is its volute casing

. The casing is designed to guide the fluid in a controlled manner, promoting efficient energy transfer and reducing the risk of cavitation. The exit of the casing is often flared, which helps in converting the velocity of the exiting fluid into pressure, maximizing the pump’s efficiency.Advantages

Vortex casing pumps offer several benefits over traditional centrifugal pumps. Firstly, they can handle fluids with higher solid content without significant risk of clogging, making them ideal for applications such as wastewater treatment and mining operations. The design minimizes wear and tear on the internal components, which translates to lower maintenance costs and longer service life.

vortex casing pump

Additionally, vortex pumps operate with low shear, allowing for the transfer of shear-sensitive materials without damage. This feature is crucial in industries such as food processing and chemical manufacturing where preserving the integrity of the material is vital.

Applications

The applications of vortex casing pumps are vast and varied. They are widely used in wastewater treatment plants for the transportation of sludge and other solids-laden liquids. In mining, they effectively handle heavy slurries, ensuring efficient and reliable operations. Additionally, vortex pumps are utilized in agricultural irrigation systems and in various industrial processes where the movement of thick liquids is required.

In the construction industry, vortex pumps play a crucial role in dewatering operations, helping to remove accumulated groundwater effectively. Their ability to handle abrasive and corrosive materials makes them suitable for environments where other pumps may fail.

Conclusion

In conclusion, vortex casing pumps are a vital component in various industries requiring reliable fluid movement, especially when dealing with challenging materials. Their unique design, which minimizes clogging and wear, coupled with low shear capabilities, makes them invaluable in modern industrial applications. Understanding the principles and advantages of vortex casing pumps can help businesses choose the right pumping solutions for their specific needs, ensuring efficiency and longevity in their operations.

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025

-

Symptoms of a Stuck Automobile Water Pump ImpellerNewsAug.22,2025

-

The Importance of Valve Castings in Water TreatmentNewsAug.22,2025

-

Welding Techniques for End Cap Stainless Steel FittingsNewsAug.22,2025

-

How to Install a Water Pump Connector ProperlyNewsAug.22,2025