Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Italian

Premium Metal Casting Products | Quality Castings Manufacturer

The Significance of Metal Casting Products in Modern Industry

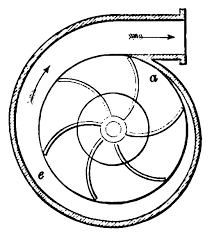

Metal casting is a foundational manufacturing process that has proven essential across various industries. It entails pouring molten metal into a mold to create objects ranging from intricate components to large structural elements. The versatility and adaptability of metal casting make it a vital technique in producing high-quality products that meet the demands of modern applications.

The Significance of Metal Casting Products in Modern Industry

One of the primary advantages of metal casting is its ability to create complex shapes and intricate designs that would be challenging or impossible to achieve through other manufacturing methods. Techniques such as sand casting, investment casting, and die casting allow manufacturers to produce items with precise dimensions and fine details, catering to the specific needs of their clients. Furthermore, metal casting facilitates the use of various materials including aluminum, iron, and steel, providing a broad spectrum of mechanical properties and aesthetic finishes.

metal casting products

In addition to versatility and design flexibility, the economic benefits of metal casting are significant. The process often requires less material waste compared to machining, where excess material is removed to achieve desired shapes. Moreover, molds can be reused for multiple castings, lowering production costs and reducing environmental impact. As industries aim to incorporate sustainable practices, the inherent efficiency of metal casting is becoming increasingly appealing.

However, the metal casting industry is continuously facing challenges, particularly relating to environmental regulations and competition from alternative manufacturing processes. As the demand for sustainable solutions grows, the industry must adapt by integrating eco-friendly practices. Innovations in alloy formulations, energy-efficient melting technologies, and better waste management strategies are being explored to enhance the sustainability of metal casting operations.

Furthermore, advancements in automation and computer-aided design (CAD) are transforming metal casting. The integration of additive manufacturing technologies, such as 3D printing, allows for the production of complex molds and cores, reducing lead times and enhancing product customization. These cutting-edge developments hold the promise of revolutionizing traditional practices, thus enhancing the overall efficiency and quality of metal cast products.

In conclusion, metal casting remains a robust and critical process in modern manufacturing, providing high-quality products across various industries. With its unique capability to produce complex shapes economically, and its adaptability to evolving technological standards, the future of metal casting looks promising. As the industry continues to embrace innovations and sustainability, the importance of metal casting products is destined to grow, solidifying their place in the global manufacturing landscape.