Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Italian

Light Metal Casting Solutions | Precision Engineering and Manufacturing

The Evolution of Light Metal Casting Innovations and Applications

Light metal casting has emerged as a pivotal technology in manufacturing, particularly due to the increasing demand for lightweight materials in various industries. The use of materials such as aluminum, magnesium, and titanium has gained traction because these metals provide substantial benefits, including high strength-to-weight ratios, corrosion resistance, and excellent thermal properties. This article explores the advancements in light metal casting processes, their applications, and the sustainable practices being implemented within the industry.

Technological Advancements in Casting

The evolution of light metal casting techniques has significantly shaped how manufacturers approach product design and production. Traditional casting processes such as sand casting and die casting have been enhanced with new technologies, including investment casting and squeeze casting. Direct metal laser sintering (DMLS) and other additive manufacturing techniques are also making waves, allowing for intricate designs that were previously deemed unfeasible.

Die casting, particularly for aluminum and magnesium alloys, has become more efficient with innovations in process control and automation. Techniques like vacuum-assisted die casting reduce porosity and improve the mechanical properties of cast components, which are critical in high-stress applications such as automotive and aerospace sectors. These advancements not only enhance performance but also reduce waste and production costs, making them attractive in competitive markets.

Applications in Various Industries

Light metal casting finds applications across a range of industries. In the automotive sector, manufacturers increasingly utilize aluminum components to reduce vehicle weight, which directly improves fuel efficiency and emissions performance. Components such as engine blocks, transmission housings, and suspension parts benefit from the lightweight nature of these metals.

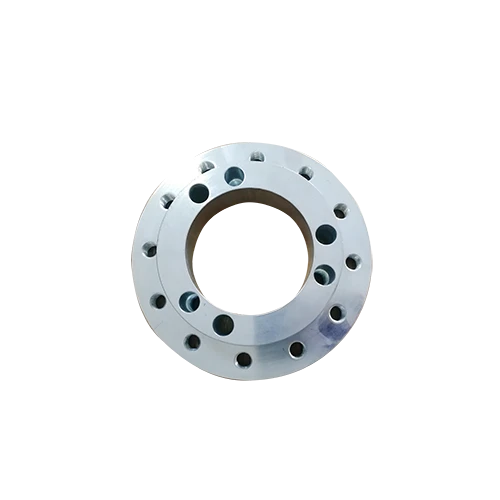

light metal casting

In the aerospace industry, weight savings are paramount. Lightweight aluminum and titanium components are essential for reducing flight operations costs by enhancing fuel efficiency. Structural elements, engine parts, and landing gear components are often produced using advanced light metal casting techniques, ensuring safety, durability, and performance.

Consumer electronics also leverage the benefits of light metal casting. Laptops, smartphones, and other devices utilize die-cast aluminum housings to not only minimize weight but also to enhance thermal management and aesthetic appeal.

Sustainability in Light Metal Casting

As environmental concerns continue to grow, the light metal casting industry is responding with sustainable practices. Recycling of aluminum is particularly notable, as it requires only a fraction of the energy needed for primary production. Many manufacturers are focused on closed-loop systems that minimize waste and maximize resource efficiency.

Moreover, innovative casting methods are being developed to reduce energy consumption and emissions during production. Companies are increasingly adopting lean manufacturing principles and integrating renewable energy sources into their operations, contributing to a more sustainable future for the casting industry.

Conclusion

Light metal casting represents a dynamic and evolving field within manufacturing. The continual advancements in casting technologies, coupled with the diverse applications across industries and a strong emphasis on sustainability, underscore the importance of this sector. As the demand for lightweight and high-performance materials increases, light metal casting will certainly play a key role in shaping the future of manufacturing and engineering solutions.