Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Italian

Exploring the Benefits of Investment Casting in Ball Valve Manufacturing

Investment Casting for Ball Valves A Key to Precision and Efficiency

Investment casting, often referred to as lost-wax casting, has become a favored manufacturing process for producing complex components such as ball valves. This method is renowned for its ability to create intricate shapes with high dimensional accuracy and excellent surface finish, making it an ideal choice for industries that require precise and reliable components.

Investment Casting for Ball Valves A Key to Precision and Efficiency

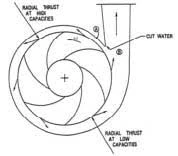

The investment casting process begins with creating a wax pattern of the desired ball valve shape. This pattern is coated with a ceramic shell that hardens as it dries. Once the shell is set, the wax is melted and drained away, leaving a cavity in the shape of the ball valve. Molten metal is then poured into this cavity, taking the form of the intricate design. After cooling, the ceramic shell is broken away, revealing the finished product.

investment casting ball valve

One of the primary advantages of investment casting for ball valves is the reduction of machining time and material waste. The precision of the cast allows for minimal post-casting operations. This not only shortens production time but also enhances cost-efficiency. Moreover, the process allows for the use of various alloy compositions, which can be tailored to meet specific application requirements, including corrosion and heat resistance.

Additionally, investment casting can accommodate a wide range of sizes and complexities, from small valves to large industrial ones. This versatility enables manufacturers to produce customized solutions that meet the unique demands of their clients. As industries increasingly seek to optimize operational efficiency while maintaining high-quality standards, the role of investment casting in ball valve production is more critical than ever.

In conclusion, investment casting presents a compelling solution for the manufacturing of ball valves. Its ability to produce complex geometries with high precision, coupled with reduced material waste and enhanced operational efficiency, makes it a preferred choice in the industry. As technology advances and the demand for reliable fluid control systems continues to grow, investment casting will likely play an even more significant role in the future of ball valve production. With its myriad benefits, investment casting not only meets current manufacturing challenges but also positions companies for success in a competitive market.