Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Italian

Advancements in Complex Metal Casting Techniques for Enhanced Precision and Efficiency

Complex Metal Casting A Comprehensive Overview

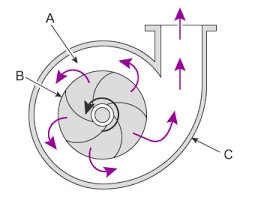

Metal casting is a time-honored process that transforms molten metal into intricate shapes and structures. Among the various casting methods available, complex metal casting stands out as a technique particularly suited for producing parts with intricate geometries, fine details, and high precision. This method has gained significant traction in industries such as aerospace, automotive, and medical equipment manufacturing, where precision and reliability are paramount.

The Process of Complex Metal Casting

Complex metal casting generally involves several key steps pattern making, mold preparation, melting, pouring, and finishing. The process begins with the creation of a pattern, which is often made from metal, plastic, or wood. This pattern is a replica of the final product and is used to form the mold cavity. The quality and accuracy of the pattern directly impact the final product's characteristics.

Mold preparation follows, where materials like sand, ceramic, or metal are used to create the mold. The choice of mold material is crucial because it affects both the casting's precision and its surface finish. For complex shapes, techniques such as lost-wax casting or shell molding are frequently employed. These methods allow for greater detail and smoother surfaces, reducing post-casting finishing work.

Next, the metal is melted in a furnace, reaching temperatures that are appropriate for the specific metal being used—this could range from aluminum to more complex alloys like titanium or superalloys. Once the metal is molten, it is carefully poured into the mold. The pouring process must be controlled meticulously to prevent defects like air pockets or inclusions, which can compromise the integrity of the final product.

After the metal has cooled and solidified, the mold is removed, yielding the raw casting. Post-casting processes such as machining, heat treatment, and surface finishing often follow. These steps enhance the mechanical properties and surface quality, ensuring the part meets stringent industry standards.

Applications of Complex Metal Casting

complex metal casting

Due to its ability to produce highly detailed components, complex metal casting is prevalent in industries with stringent performance requirements. In the aerospace industry, cast parts are used in components like turbine blades and structural elements that need to withstand extreme temperatures and pressures. The precision and strength of cast parts are vital, as any failure could have catastrophic consequences.

In the automotive sector, complex metal casting is used for engine blocks, transmission housings, and other critical components

. The lightweight nature of cast aluminum and magnesium allows manufacturers to reduce the overall vehicle weight, thus enhancing fuel efficiency without sacrificing performance.The medical field also benefits from complex metal casting. Instruments, surgical tools, and even prosthetic devices can be produced with high precision and tailored designs that fit specific medical needs. The ability to create complex geometries facilitates the development of innovative medical solutions.

Challenges and Future Directions

Despite its advantages, complex metal casting is not without challenges. The processes can be costly, and achieving consistent quality often requires advanced technologies and skilled labor. Additionally, environmental concerns regarding waste and emissions from melting processes must be addressed.

Looking to the future, the integration of 3D printing technology into metal casting processes holds great promise. By creating patterns or even molds directly through additive manufacturing, manufacturers can reduce costs and lead times significantly. As industries continue to evolve, the demand for complex metal castings will likely grow, pushing the boundaries of technology and material science.

In summary, complex metal casting is a vital manufacturing process that offers significant advantages for producing intricate and high-performing components. As technology advances, it is poised to meet the increasing demands of modern industries while addressing environmental and efficiency concerns.