Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Italian

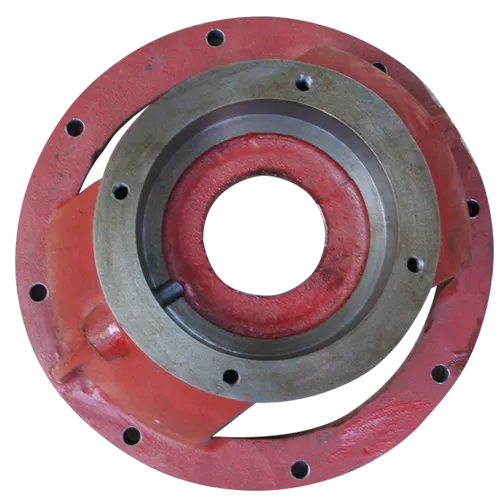

Cast Iron Pump Casing - Durable and Reliable Solutions

The Importance of Cast Iron Pump Casings in Modern Engineering

Cast iron pump casings are a fundamental component of many pumping systems utilized in various industries. These casings serve several essential functions, including providing structural support, protecting internal components, and facilitating efficient fluid movement. The unique properties of cast iron make it an ideal material for manufacturing pump casings, ensuring longevity and reliability in demanding environments.

One of the most significant advantages of cast iron is its excellent strength-to-weight ratio. The material can withstand high pressures and temperatures without deforming, making it suitable for heavy-duty applications such as wastewater treatment, chemical processing, and power generation. Furthermore, cast iron exhibits good corrosion resistance, especially when coated or treated, which is crucial in preventing degradation from the transported fluids.

In addition to its mechanical properties, cast iron’s ability to dampen vibrations is another key benefit. Pumps can generate considerable vibrations during operation, which can lead to wear and tear on mechanical components. The sound-dampening characteristics of cast iron help reduce noise levels and prolong the lifespan of the pump by minimizing stress on its parts.

cast iron pump casing

Moreover, cast iron can be easily cast into complex shapes, allowing for the precise design of pump casings that optimize fluid flow and reduce turbulence. This ability to create intricate geometries not only enhances the performance of the pump but also allows for more efficient energy consumption. As energy efficiency becomes increasingly important in industrial processes, the role of well-designed cast iron casings cannot be overstated.

Furthermore, cast iron is a cost-effective material. Although the initial production costs may be higher than some alternatives, the durability and low maintenance requirements of cast iron pump casings lead to reduced operational costs over time. Industries often prefer cast iron for its balance of affordability and performance, making it a popular choice for new installations and replacements alike.

In conclusion, cast iron pump casings play a vital role in the functionality and efficiency of pumping systems across various sectors. Their strength, vibration-dampening properties, versatility in design, and cost-effectiveness make them an excellent choice for engineers and operators. As technology evolves and industries continue to seek out efficient and durable solutions, the relevance of cast iron in pump manufacturing remains indisputable. Ensuring the integrity and functionality of these casings contributes to the overall reliability and effectiveness of pumping systems, essential for modern industrial operations.

-

superior-aluminum-castings-in-automotive-engine-partsNewsAug.22,2025

-

common-materials-used-in-fan-housing-manufacturingNewsAug.22,2025

-

symptoms-of-a-stuck-automobile-water-pump-impellerNewsAug.22,2025

-

the-importance-of-valve-castings-in-water-treatmentNewsAug.22,2025

-

welding-techniques-for-end-cap-stainless-steel-fittingsNewsAug.22,2025

-

how-to-install-a-water-pump-connector-properlyNewsAug.22,2025