Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Italian

1 inch 4 inch pipe cap specifications and uses for plumbing needs

Understanding 1 4 Inch Pipe Caps Functionality, Applications, and Selection

When it comes to plumbing and piping systems, various fittings play crucial roles in ensuring the efficient flow of fluids, maintaining pressure, and connecting different sections of a pipeline. Among these fittings, pipe caps often serve a significant purpose, particularly the 1 4 inch pipe cap. This article delves into the specifications, functionalities, applications, and considerations for selecting a pipe cap, providing a well-rounded perspective on this essential piping component.

What is a Pipe Cap?

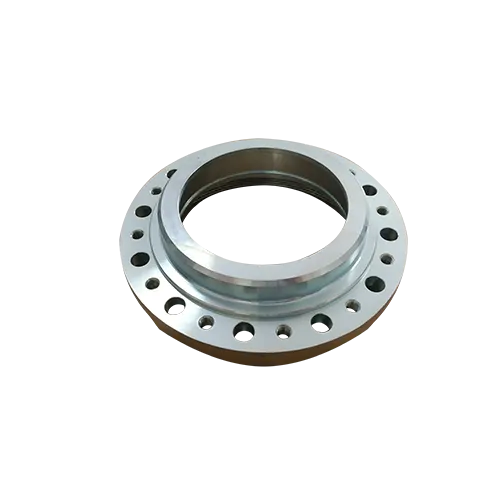

A pipe cap is a type of fitting used to close off the end of a pipe. Essentially acting as a cap for the pipe, it prevents the flow of substances within the pipeline from escaping. Pipe caps are commonly found in various materials, including PVC, stainless steel, carbon steel, and more, making them versatile for numerous applications.

Specifications of 1 4 Inch Pipe Cap

The designation 1 4 inch refers to the nominal diameter of the pipe cap. While the actual dimensions may slightly differ due to manufacturing standards and tolerances, it indicates that the cap fits on a pipe of a 1¼ inch nominal size. This common measurement means it is frequently used in plumbing and industrial applications. The pipe cap must be compatible with the pipe material and the pressure requirements of the system in which it is installed.

Functionality

The primary function of a 1 4 inch pipe cap is to seal the end of a pipe. By providing a secure closure, it serves several critical roles

1. Prevent Leaks A properly fitted cap ensures that no fluid can escape from the end of the pipe, which is essential for maintaining system pressure and preventing loss of valuable fluids. 2. Protection from Contaminants By capping the pipe, contaminants are kept out, preserving the integrity of the pipeline contents.

3. System Maintenance In many cases, caps are used as temporary closures during maintenance or repairs, allowing technicians to work on specific sections without disrupting the entire system.

4. Flow Direction Control In systems where pipe sections need to be isolated, caps can be used to stop flow in specific areas while allowing for the control of movement in others.

Applications

1 4 inch pipe cap

The applications for a 1 4 inch pipe cap are vast and varied

. They are commonly found in- Plumbing Systems In residential and commercial buildings, pipe caps are used to terminate water lines or drainage systems. - Industrial Pipelines Heavy industries use pipe caps in their fluid transport systems to manage and control the flow of chemicals and other materials. - Fire Protection Systems Caps are used in fire sprinkler systems for testing and ensuring that the integrity of the piping system remains intact before activation. - Oil and Gas In oil and gas operations, pipe caps are essential for safeguarding pipeline ends, particularly during construction or maintenance work.

Selecting the Right Pipe Cap

When choosing a 1 4 inch pipe cap, several factors should be considered to ensure it meets your specific needs

1. Material Compatibility Choose a cap made from the same material as the pipe to ensure a good seal and prevent any potential reactions between different materials.

2. Pressure Rating Ensure that the cap can withstand the pressure that will be present in the system. Pipe caps come in various pressure ratings, so it is essential to verify this feature before purchase.

3. Temperature Resistance Depending on the application, consider the temperature rating of the cap material to prevent failure under extreme conditions.

4. Connection Type The method of connection (threaded, welded, or slip-on) should correspond to the pipe end type to ensure a secure fit.

5. Standards Compliance Ensure that the pipe cap complies with industry standards for safety and reliability, as this can vary by application and region.

Conclusion

A 1 4 inch pipe cap is an often-overlooked but fundamentally essential component of piping systems. Its role in sealing pipes, preventing leaks, and protecting the fluid system cannot be understated. With its diverse applications across various industries, selecting the right pipe cap according to material, pressure, and temperature requirements is vital for the overall integrity and functionality of piping solutions. Whether for plumbing, industrial applications, or specialized systems, understanding the significance of pipe caps ensures optimized performance and reliability in fluid management.