Mobile:+86-311-808-126-83

Email:info@ydcastings.com

German

Titanium Turbo Housing - High Performance Turbo Components

Understanding Titanium Turbo Housing The Pinnacle of Performance Engineering

In the world of automotive performance, advancements in technology constantly push the boundaries of what is achievable. One such innovation is the titanium turbo housing, a critical component that has garnered attention from both enthusiasts and engineers alike. This article delves into the significance of titanium turbo housing, exploring its benefits, applications, and impact on vehicle performance.

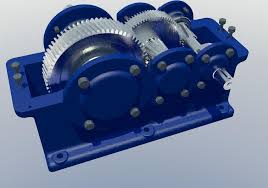

Turbochargers are integral to modern engines, allowing for greater power output by increasing air intake. The housing of a turbocharger, typically made from cast iron or aluminum, plays a crucial role in its efficiency and durability. However, the introduction of titanium into turbo housing design marks a transformative shift in automotive engineering. Titanium is revered for its remarkable strength-to-weight ratio, corrosion resistance, and ability to withstand high temperatures, making it an ideal choice for turbo applications.

One of the most significant advantages of titanium turbo housing is its lightweight nature. Traditional materials, such as cast iron, can add unnecessary weight to the vehicle, which can negatively impact acceleration and handling. By substituting aluminum or cast iron with titanium, manufacturers can reduce weight significantly, resulting in a more responsive vehicle. This reduction in mass can enhance acceleration, braking, and overall driving dynamics, providing a thrilling experience for drivers.

titanium turbo housing

Moreover, titanium turbo housing can endure higher operating temperatures. Turbochargers generate significant heat during operation, and the ability of titanium to maintain structural integrity and performance at elevated temperatures is a game-changer. This characteristic reduces the risk of thermal fatigue and failure, leading to increased reliability and longevity of the turbocharger system. Consequently, vehicles equipped with titanium turbo housing can maintain peak performance under demanding conditions, whether on the racetrack or during daily driving.

The corrosion resistance of titanium also extends the lifespan of turbo housings. In high-performance environments where exposure to elements like moisture, salt, and other corrosive substances is common, titanium's durability helps prevent degradation. This resilience translates into lower maintenance costs and fewer replacements, making titanium an economically viable option in the long run.

In conclusion, titanium turbo housing represents a significant advancement in automotive engineering, combining lightweight attributes, high-temperature tolerance, and exceptional durability. As the automotive industry continues to prioritize performance and efficiency, the adoption of titanium components is likely to increase. For enthusiasts seeking to enhance their vehicle's performance, investing in titanium turbo housing could be the ultimate upgrade, unlocking new levels of power and reliability. Whether on the street or the track, this cutting-edge technology is set to redefine performance standards in the years to come.