Mobile:+86-311-808-126-83

Email:info@ydcastings.com

German

Exploring the Design and Functionality of Submersible Pump Casings in Modern Applications

Understanding Submersible Pump Casings Design, Importance, and Applications

Submersible pumps are vital components in various industries, especially in water management, sewage treatment, and agricultural irrigation. At the core of these pumps lies the casing, a critical part that plays an essential role in the pump's overall performance, efficiency, and durability.

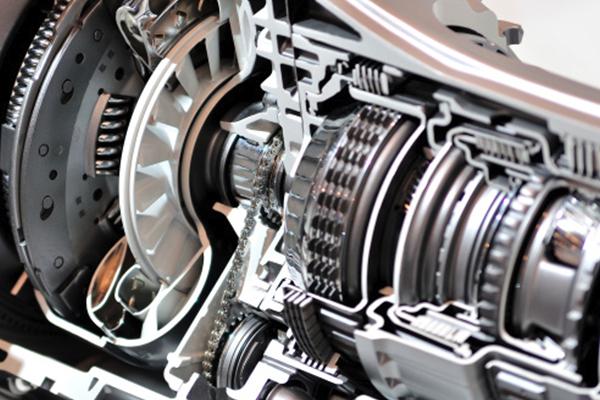

A submersible pump casing is designed to house the motor and impeller apparatus, allowing the pump to function efficiently underwater. Typically made from robust materials like stainless steel or thermoplastic, the casing must withstand the external pressure of the surrounding fluid and resist corrosion, especially in harsh environments such as sewage or saltwater applications. The choice of material is crucial; stainless steel offers high strength and resistance to rust, while thermoplastic options are lighter and often used in less demanding applications.

The design of submersible pump casings varies depending on the specific application needs. For example, sewage pumps often have casings designed to handle solids and debris without clogging, while well pumps have more streamlined designs for deep-water applications. Manufacturers often optimize the shape and size of the casing to enhance hydraulic efficiency, reduce turbulence, and facilitate smooth water flow. Proper engineering ensures that the casing minimizes energy loss and maximizes the pump's operational lifespan.

submersible pump casing

One crucial aspect of submersible pump casings is their capability to provide effective sealing. Seals prevent water from entering the motor compartment, protecting the electrical components from damage and ensuring safe operation. High-quality seals and prudent design are necessary to mitigate risks associated with water ingress, as even a small amount of water can lead to catastrophic pump failure.

Moreover, the casings must cater to specific installation environments, such as ensuring compatibility with varying fluid densities and temperatures. In agricultural settings, for instance, the pump may be submerged in water with varying sediment loads, which requires a casing design that can efficiently handle such conditions without compromising performance.

In addition to their technical aspects, submersible pump casings also play a role in maintenance. Easy access to the casing for repairs and inspections can significantly reduce downtime and maintenance costs. Manufacturers are increasingly designing casings with user-friendly features that enable quicker disassembly and reassembly.

In conclusion, the submersible pump casing is an integral part of pump technology, influencing performance, durability, and maintenance efficiency. Understanding its design and functionality helps users select the right pump for their needs and ensures optimal operation in diverse applications. As industries continue to evolve and demand more efficient water management solutions, advancements in casing technology are likely to play a pivotal role in shaping the future of submersible pumps.