Mobile:+86-311-808-126-83

Email:info@ydcastings.com

German

High-Quality Die Casting Products | Precision Engineering Solutions

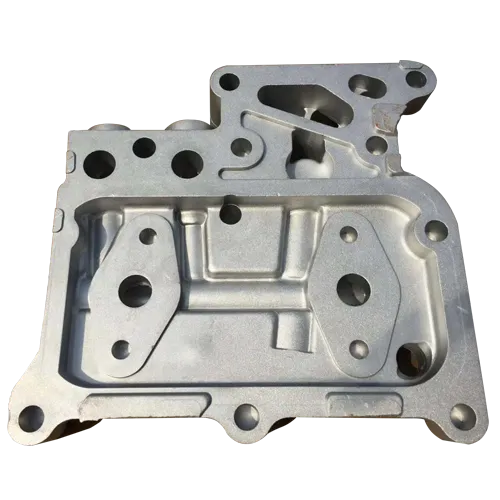

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is widely used to produce complex-shaped components with excellent surface finish and dimensional accuracy. The die casting process primarily utilizes non-ferrous metals such as aluminum, zinc, and magnesium, which are favored for their lightweight and corrosion-resistant properties.

The production of die casting products typically involves several steps. First, the die, which is the mold used to shape the product, is created with precision to ensure that the final piece meets the required specifications. The die can be made from various materials, including steel or aluminum, depending on the complexity and volume of the production.

Once the die is prepared, the molten metal is injected into it under high pressure. This pressure forces the metal to fill the cavities completely, ensuring that even the most intricate details are captured. After the metal cools and solidifies, the die is opened, and the finished product is ejected. This process allows for rapid production rates, making it an ideal choice for manufacturing high volumes of parts.

One of the most significant advantages of die casting is the ability to produce highly complex shapes with tight tolerances. This is particularly beneficial in industries such as automotive, aerospace, and electronics, where precision components are crucial. For example, automotive manufacturers often utilize die casting to create intricate engine and transmission parts, ensuring optimal performance and reliability.

die casting products

In addition to complex shapes, die casting products often feature a superior surface finish

. The smooth surfaces reduce the need for secondary machining processes, minimizing production time and costs. Additionally, the durability and strength of die-cast components make them suitable for a wide range of applications, from consumer electronics to heavy machinery.Die casting is also a more environmentally friendly manufacturing option compared to other metalworking processes. The process generates minimal waste, as excess material can often be melted down and reused in future production runs. Furthermore, the ability to use recycled metals in die casting helps reduce the overall environmental impact.

As technology continues to advance, innovations in die casting techniques are emerging. For instance, the introduction of advanced robotics in the production process increases efficiency and precision, allowing manufacturers to meet the growing demand for customized die casting products.

In conclusion, die casting is a vital manufacturing process that plays a crucial role in producing high-quality, precision components across various industries. Its ability to create complex shapes, coupled with excellent surface finishes and environmental benefits, makes it a preferred choice for manufacturers aiming to deliver durable and reliable products. With ongoing advancements in technology, the future of die casting looks promising, paving the way for even more innovative applications.