Mobile:+86-311-808-126-83

Email:info@ydcastings.com

German

Feb . 20, 2025 07:43

Back to list

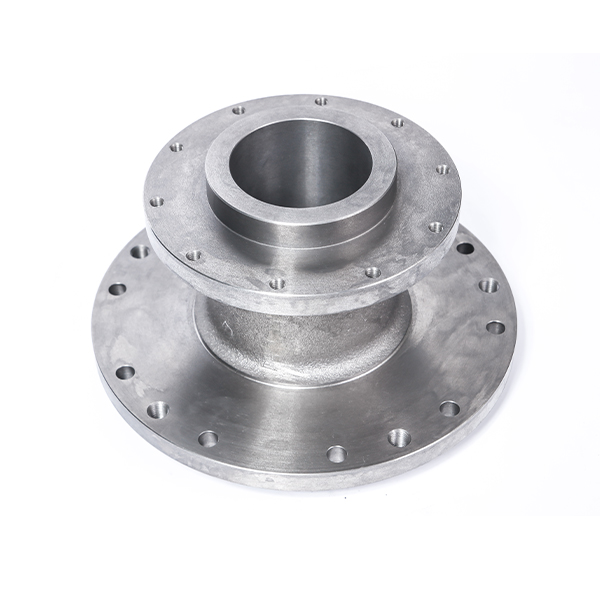

stainless steel casting

A352 steel is a versatile and robust alloy, gaining widespread use in various industries due to its remarkable properties. Fabricated primarily for high-pressure and low-temperature environments, this material provides a reliable solution for harsh conditions where typical steel might fail. Businesses that require durable and resilient materials often turn to A352 steel, making it crucial to understand its benefits and applications thoroughly.

The expertise required to utilize A352 steel effectively comes from years of industrial research and application. Engineers and metallurgists continually analyze the material's performance under various conditions to optimize its usage. Through meticulous testing and evaluation, guidelines for welding, heat treatment, and fabrication have been established, ensuring that A352 steel products meet the rigorous standards expected in critical applications. Trust in A352 steel’s capabilities is built on a foundation of consistent delivery of results across numerous projects. Case studies highlighting its use in successful projects reinforce its reputation as a dependable material. For instance, offshore drilling operations employing A352 steel components have reported significant reductions in maintenance costs and downtime, thus confirming the material's long-term value and reliability. As industries advance, the demand for materials that combine strength, durability, and environmental resistance continues to grow. A352 steel meets these demands with its proven track record and enduring qualities. Companies choosing A352 steel benefit from a product that not only meets immediate structural needs but also offers long-term savings and efficiency gains by reducing the frequency of replacements and repairs. Businesses seeking reliable suppliers must ensure the source has a history of supplying high-quality A352 steel and adheres to stringent quality control standards. It is advisable to partner with manufacturers that offer comprehensive support and detailed documentation on the material's specifications and usage guidelines. In conclusion, A352 steel stands out as an exemplary material for industries requiring robust, durable, and corrosion-resistant solutions. Its application across various sectors underscores its versatility and indispensability. Industrial leaders considering A352 steel can rely on its proven performance, backed by expert research and substantial industry trust. As demands for advanced materials escalate, A352 steel remains a cornerstone for safety, efficiency, and innovation in industrial operations.

The expertise required to utilize A352 steel effectively comes from years of industrial research and application. Engineers and metallurgists continually analyze the material's performance under various conditions to optimize its usage. Through meticulous testing and evaluation, guidelines for welding, heat treatment, and fabrication have been established, ensuring that A352 steel products meet the rigorous standards expected in critical applications. Trust in A352 steel’s capabilities is built on a foundation of consistent delivery of results across numerous projects. Case studies highlighting its use in successful projects reinforce its reputation as a dependable material. For instance, offshore drilling operations employing A352 steel components have reported significant reductions in maintenance costs and downtime, thus confirming the material's long-term value and reliability. As industries advance, the demand for materials that combine strength, durability, and environmental resistance continues to grow. A352 steel meets these demands with its proven track record and enduring qualities. Companies choosing A352 steel benefit from a product that not only meets immediate structural needs but also offers long-term savings and efficiency gains by reducing the frequency of replacements and repairs. Businesses seeking reliable suppliers must ensure the source has a history of supplying high-quality A352 steel and adheres to stringent quality control standards. It is advisable to partner with manufacturers that offer comprehensive support and detailed documentation on the material's specifications and usage guidelines. In conclusion, A352 steel stands out as an exemplary material for industries requiring robust, durable, and corrosion-resistant solutions. Its application across various sectors underscores its versatility and indispensability. Industrial leaders considering A352 steel can rely on its proven performance, backed by expert research and substantial industry trust. As demands for advanced materials escalate, A352 steel remains a cornerstone for safety, efficiency, and innovation in industrial operations.

Next:

Related PRODUCTS