Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding Connections for Cast Iron Pipe Systems and Their Applications

Understanding Cast Iron Pipe Connections

Cast iron pipes have been a fundamental component of plumbing and drainage systems for centuries. Renowned for their durability and strength, these pipes are often used in both residential and commercial applications. When it comes to installing cast iron pipe connections, understanding the various types and methods is crucial for ensuring a leak-proof and efficient plumbing system.

There are primarily two types of cast iron pipe connections hub-and-spigot and no-hub. The hub-and-spigot connection involves a bell-shaped end (the hub) that fits over the plain end (the spigot) of another pipe. This type of connection typically uses lead and oakum for sealing, providing a watertight joint. While traditional, it requires skilled craftsmanship and has become less common in modern installations.

On the other hand, no-hub connections are popular for their ease of installation. These connections consist of plain ends joined together with a rubber or neoprene coupling and secured with stainless steel bands. This method eliminates the need for lead and oakum, making it faster and safer. No-hub connections are especially advantageous in rehabilitation projects, where existing pipes may need to be joined to newer systems.

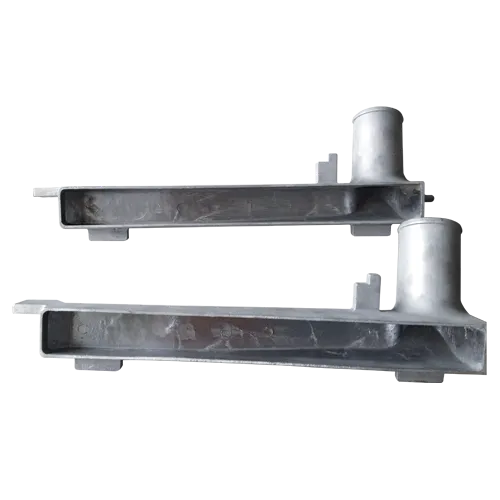

cast iron pipe connections

Proper alignment and fitting of cast iron pipes are essential to prevent strain and deformation, which can lead to leaks or breaks. When connecting cast iron pipes, professionals often utilize a leveling tool and ensure pipes are cut cleanly and fitted snugly. Moreover, the use of appropriate gaskets and seals helps in accommodating any potential expansion or contraction due to temperature changes.

Regular maintenance and inspection of cast iron pipe connections are imperative. Although cast iron is resistant to rust and corrosion, it can still be affected over time. Common issues include leaks at the joints and the buildup of debris within the pipes. Using camera inspection technology can help identify problem areas without the need for invasive procedures.

In conclusion, understanding the various types of cast iron pipe connections is vital for anyone involved in plumbing work. Whether using traditional hub-and-spigot methods or modern no-hub techniques, the focus should always be on quality installation and regular maintenance to prolong the lifespan of the plumbing system. With the right knowledge and tools, cast iron pipes can offer reliable and long-lasting performance for years to come.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025