Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Design and Efficiency of A320 Engine Impellers for Enhanced Performance

Understanding the A320 Impeller A Critical Component in Aviation Technology

The A320, a popular narrow-body aircraft manufactured by Airbus, has transformed the airline industry since its first flight in 1987. One of the key components that contribute to the aircraft's efficiency and performance is the impeller, a vital element within the engines that play a crucial role in thrust generation and overall aerodynamic performance.

Understanding the A320 Impeller A Critical Component in Aviation Technology

The design and efficiency of the impeller greatly influence the engine’s overall performance. An optimized impeller can lead to a reduction in fuel consumption, which is a critical aspect in commercial aviation where operational costs are tightly controlled. The A320 family of aircraft is known for its fuel efficiency, and the design of the impeller is one of the contributing factors to this characteristic. By reducing drag and maximizing airflow through the engine, the impeller ensures that the A320 maintains excellent operational efficiency, allowing airlines to save on fuel costs and operate more environmentally friendly flights.

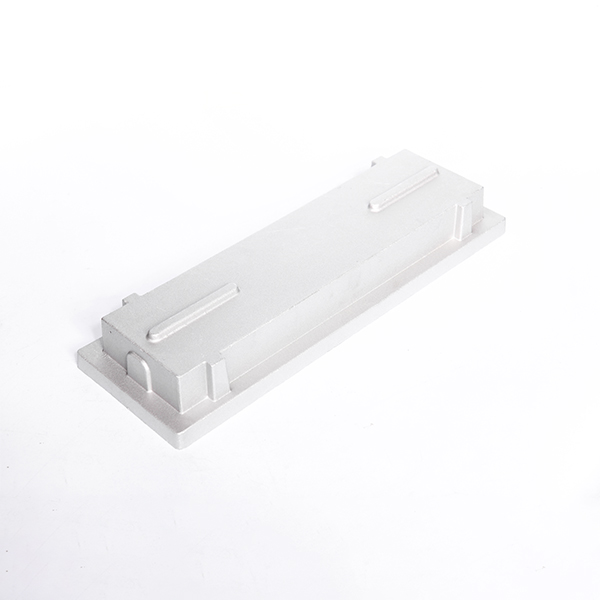

a320 impeller

Advancements in materials and manufacturing processes have also significantly impacted the design of the impeller for engines used in the A320. Modern impellers are often made from advanced composites and alloys that offer better durability and resistance to high temperatures and stresses. This enhances the reliability of the engines and extends their operational lifespan, which is an important consideration for airlines that rely on their fleets for long-haul operations.

Additionally, the aerodynamic design of the impeller has seen improvements over the years. Computational fluid dynamics (CFD) has allowed engineers to simulate airflow and optimize the shape of the impeller blades. These advancements have resulted in impellers that not only enhance thrust but also reduce noise levels, contributing to a more pleasant flying experience for passengers and minimizing the environmental impact of air travel.

The significance of the A320 impeller extends beyond its mechanical functions. It represents a culmination of engineering expertise and innovation in the aviation industry. As airlines continue to aspire towards greener technologies and more efficient operations, the role of components such as the impeller will only become more vital. As new models and technologies emerge, the continuous evolution of the impeller design will play a pivotal part in shaping the future of air travel.

In conclusion, the A320 impeller is a prime example of how critical engineering components influence the performance and efficiency of modern aircraft. Its impact on fuel economy, engine performance, and overall flight experience underscores the importance of ongoing research and development in aviation technology. As the industry strives towards sustainability and efficiency, the evolution of the impeller remains integral to the aircraft's success and the future of commercial aviation.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025